How does Exponent go beyond the checklist to deliver effective, multidisciplinary manufacturing auditing?

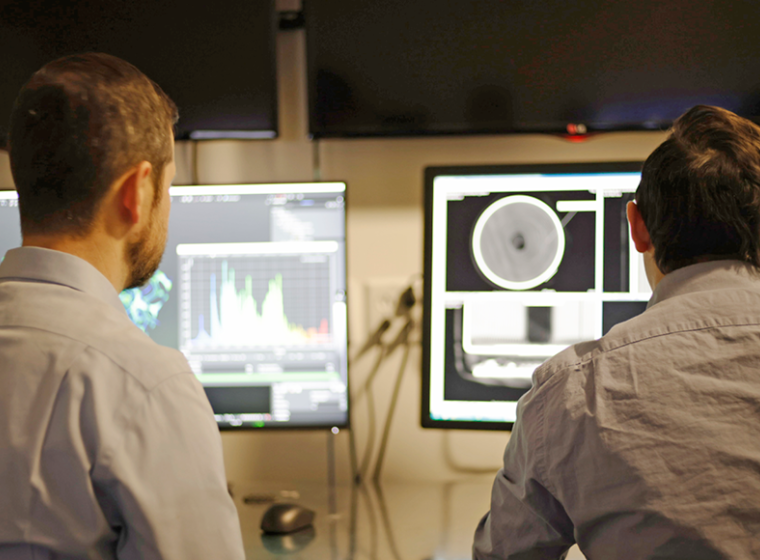

Exponent's manufacturing auditors are a multidisciplinary team of experienced engineers and scientists who surpass checking boxes and giving cursory factory assessments. Clients engage us to implement systematic auditing standards to help them vet suppliers, assess production quality and efficiency, and avoid potential operational and safety risks.

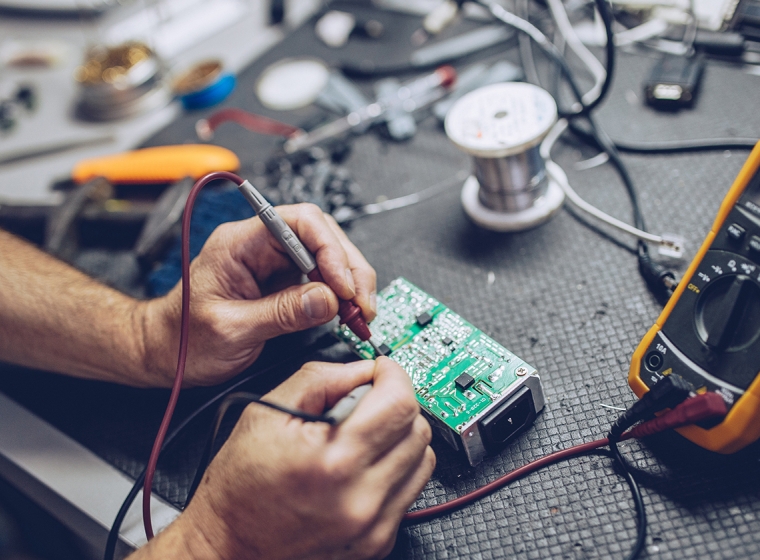

Our team has the technical training and hands-on experience to bridge the gap between managerial oversight and engineering know-how. Our expertise also includes reviewing batteries, medical devices, software, and consumer electronics.

Exponent is certified as an ISO 9001:2008 and ISO 13485 lead auditor, and our quality engineers utilize current ISO 33000 series standards to conduct software process assessments.

services

For 50+ years, we’ve thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

• Amorphous silicon deposition systems

• Automotive components

• Battery systems and cell quality

• Building control systems

• Consumer electronics

• Heaters and air conditioners

• Medical devices and FDA clearance manufacturing requirements

• Printing

• Software products

• Consulting for organizations using ISO 9001:2008, ISO 13485, and ISO 33000 standards

• PFMEA and general risk assessments

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Software & Computer Systems Support

Insights and solutions for the design, development, and analysis of software prototypes, products, and platforms.

Systems & Controls

Critical systems and controls support, from missile guidance and ADAS technology to utility power generation and consumer electronics.

Electrical Devices & Consumer Products

Product design validation, risk assessment, product launch support, failure analysis, product recalls, and more.

Power & Energy

Multidisciplinary support for high-power energy systems of all sizes in a variety of applications.

Batteries & Energy Storage

Supercharge performance, reliability, and safety across all stages of the battery and energy storage product lifecycle.

Electrical Engineering & Computer Science Expertise for Intellectual Property

Leverage best-in-class electrical engineering and computer science consulting for IP challenges

Product Development

Expert electrical engineering and computer science consulting services for every stage of your product journey.

Technical Forensics

Failure analyses, predictive modeling, and accident reconstruction for valuable insights that help you prevent accidents and failures.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Corporate Vice President, Practice/Office Director and Principal

Office Director and Principal Engineer

Senior Managing Engineer

Insights