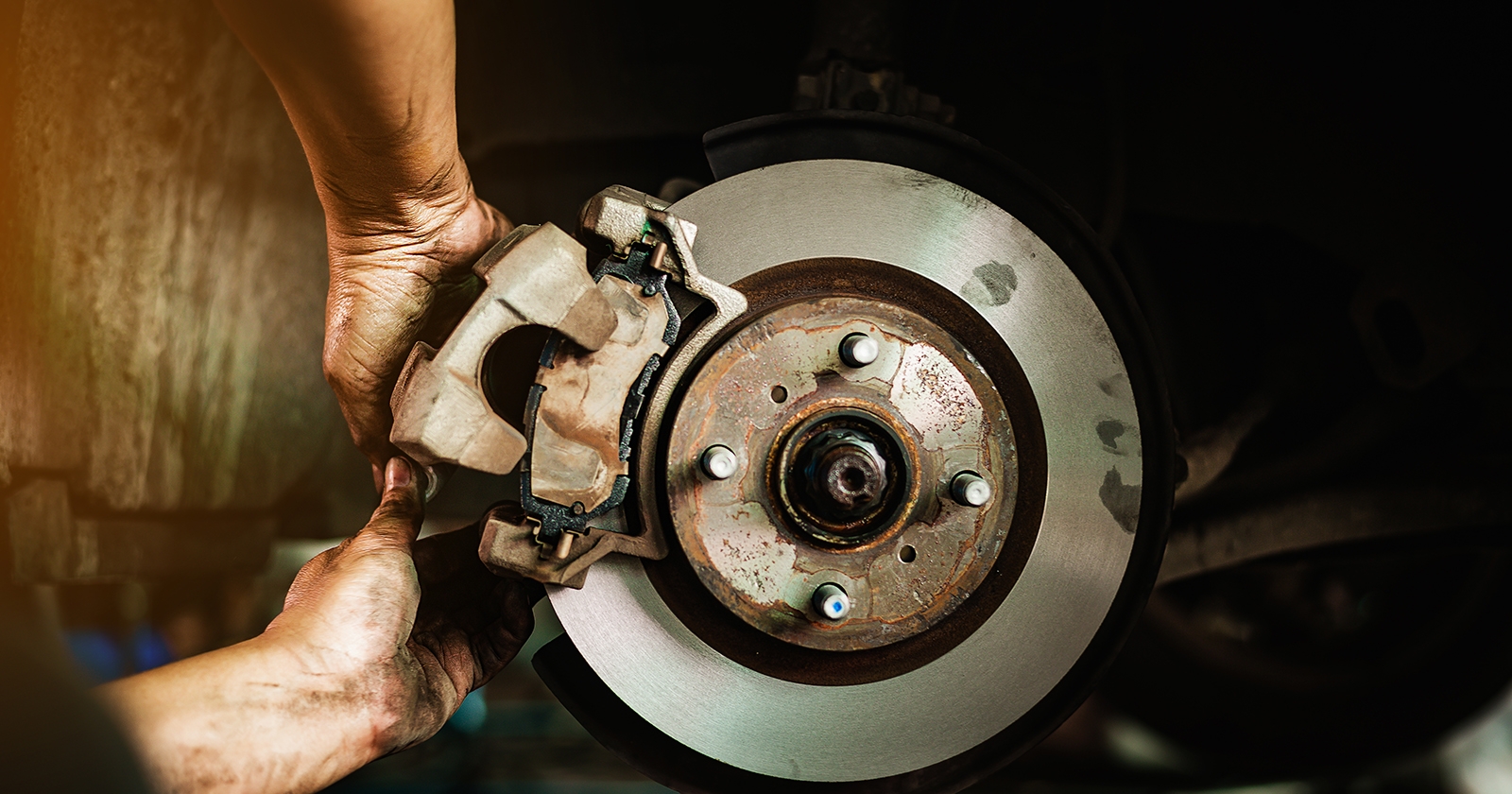

Is Enhanced Cleaning During COVID-19 Damaging Your Industrial Equipment?

How does Exponent's multidisciplinary approach deliver objective answers to materials challenges?

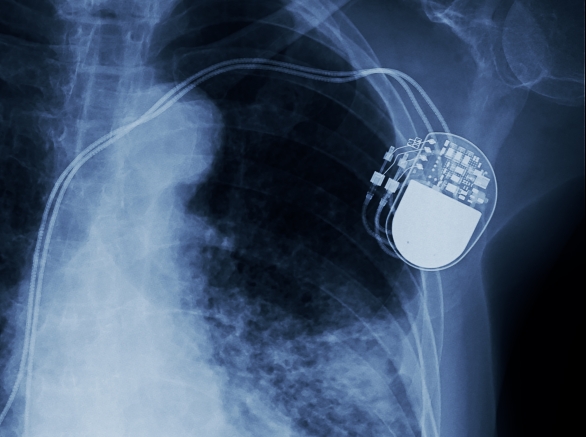

Exponent is uniquely positioned to confront a wide range of long-standing and emerging materials challenges. Our multidisciplinary teams — composed of materials, mechanical, structural, electrical, and chemical engineers, as well as electrochemists, statisticians, chemists, and polymer scientists — provide next-generation testing at our state-of-the-art-facilities combined with advanced analysis to help you accurately understand corrosion mechanisms and how to mitigate them. Exponent provides field investigations, direct and root cause assessments, and development of corrosion control programs, as well as supports navigating regulatory requirements.

Summary of Services

For 50+ years, we've thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Batteries & Energy Storage

Supercharge performance, reliability, and safety across all stages of the battery and energy storage product lifecycle.

![[MCE] Factory Auditing & Assembly Line Evaluations - view of assembly line floor](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1320950393.jpg?itok=NSEByy9p)

Materials & Corrosion Industry Expertise

Materials science engineering expertise tailored for every industry.

Product & Process Advisory

Materials and corrosion engineers assist with materials issues at every stage of your product or process lifecycle.

Materials, Metallurgy & Corrosion Engineering Capabilities

Assess corrosion risks and follow best practices in materials selection, operations, and corrosion control for metals.

Materials & Corrosion Engineering Expertise for Disputes

Technical scientific support for disputes involving materials and corrosion.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President for US and London Offices and Principal Engineer

Group Vice President and Principal Engineer

Senior Fellow and Principal Scientist

Practice Director, Director of Asia Offices and Principal Engineer

Office Director and Principal Engineer

Office Director and Principal Engineer