Diagnosing Failures of Thin Films Across the Product Life Cycle

How does Exponent's multidisciplinary approach help improve the long-term performance of paints and coatings?

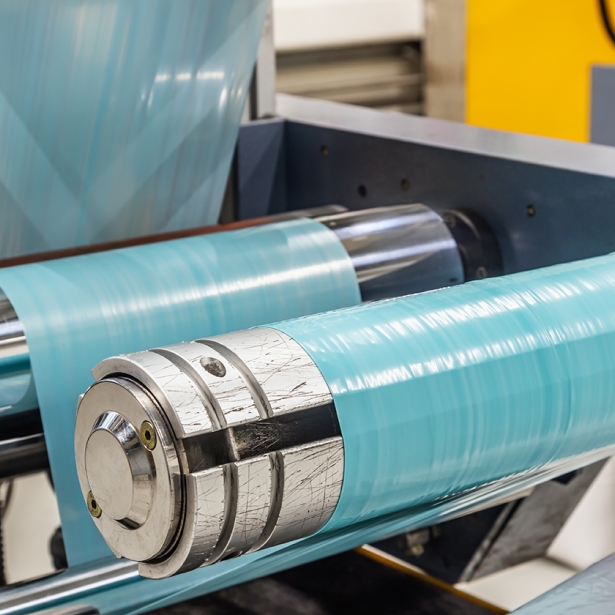

Paints and coatings require the right formulation, adhesion, and physical properties to meet quality, durability, and regulatory compliance standards. Whether for industrial, architectural, automotive, semiconductor, optical, or medical applications, Exponent's multidisciplinary teams provide rigorous science and evidence-backed answers for a range of paints and coatings challenges.

Our quantitative approach supports decisions regarding use of coatings in a variety of applications, from nanometer-scale thin films to paints and protective coatings hundreds of microns thick. Our industry experience combined with our background in organic and inorganic materials and manufacturing processes makes us uniquely qualified to provide expertise in surface characterization, materials science, chemistry, mechanics, and process knowledge.

Exponent performs laboratory tests based on industry standards, including ASTM International, the Association for Materials Protection and Performance, and the American Architectural Manufacturers Association, to investigate paint and coating failures. We also use various analytical methods, such as electrochemical impedance spectroscopy to evaluate coating quality and the long-term performance of coatings in corrosive environments.

Consulting and compliance expertise.

We deliver support on regulatory compliance with surface coating Reasonably Available Control Technology, Best Available Control Technology, and the National Emission Standard for Hazardous Air Pollutants regulations. In addition, we frequently compile pollution prevention strategies and make recommendations to reduce hazardous waste.

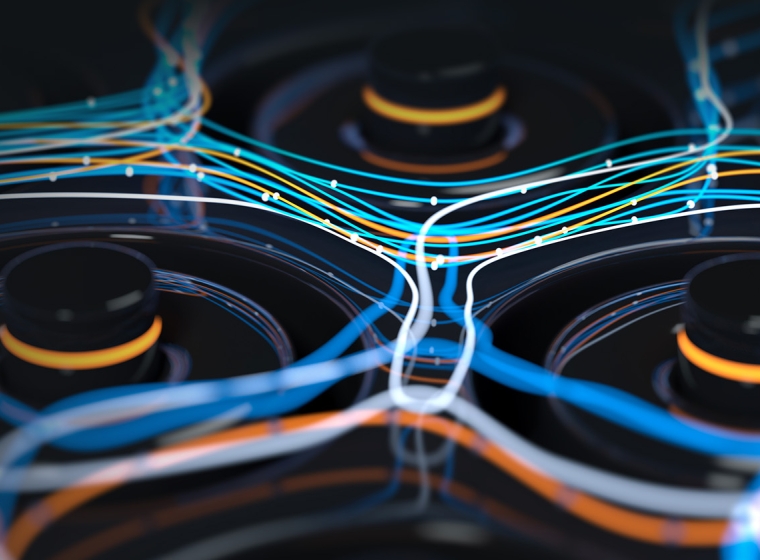

Thin films.

We assist clients across industries in solving difficult problems related to device and thin-film failures. Exponent's engineers apply a fundamental understanding of materials and processes to address concerns related to environmental degradation, adhesion, residual or applied stresses, fracture toughness, fatigue, and other challenges related to the successful integration and reliability of the device.

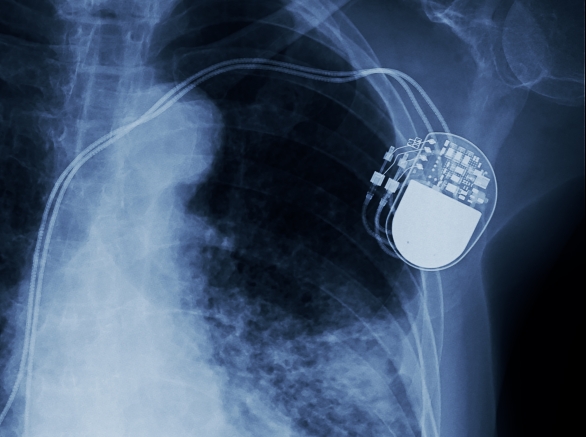

Coatings for medical devices.

Protective and functional coatings are increasingly incorporated into medical devices where they can provide benefits such as biocompatibility, passivation, and drug delivery. Our scientists and engineers can assist with materials selection, accelerated testing, characterization, failure analysis, and intellectual property analysis.

Services

For 50+ years, we’ve thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

• Paints and coatings formulation consulting

• Adhesion and physical properties consulting

• Application processes analysis

• Regulatory compliance consulting

• Durability assessment

• Material selection

• Surface preparation methods consulting

• Stress corrosion cracking and environmentally assisted cracking analysis

• Electrochemical impedance spectroscopy analysis

• Powder coating technologies consultation

• Consultation and expertise in sol gel coating, dip coating, protective coatings, functional coatings, thin films, and medical device coatings

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Batteries & Energy Storage

Supercharge performance, reliability, and safety across all stages of the battery and energy storage product lifecycle.

![[MCE] Factory Auditing & Assembly Line Evaluations - view of assembly line floor](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1320950393.jpg?itok=NSEByy9p)

Materials & Corrosion Industry Expertise

Materials science engineering expertise tailored for every industry.

Product & Process Advisory

Materials and corrosion engineers assist with materials issues at every stage of your product or process lifecycle.

Materials, Metallurgy & Corrosion Engineering Capabilities

Assess corrosion risks and follow best practices in materials selection, operations, and corrosion control for metals.

Materials & Corrosion Engineering Expertise for Disputes

Technical scientific support for disputes involving materials and corrosion.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President for US and London Offices and Principal Engineer

Senior Fellow and Principal Scientist