How does Exponent assist clients in analyzing vibrations in complex mechanical systems?

Many mechanical failures occur because dynamic or vibrational considerations were overlooked during mechanical design. Exponent's mechanical engineers help clients design more resilient machinery and diagnose root causes of vibration damage in existing equipment.

We have diverse experience in a wide variety of industries and applications.

Our experience in vibrations analysis spans power generation equipment, heavy machinery, transportation systems and components, consumer electronics, medical devices, as well as complex and highly integrated computerized systems across a wide range of industries.

Exponent's vibration specialists can locate possible causes of vibration in existing systems and identify methods to mitigate excessive vibrations through comprehensive analysis and testing. Our staff has expertise in evaluating a wide variety of vibration-related applications, including:

- Providing front-end design guidance to prevent vibration issues

- Measuring system vibrations for diagnostic purposes

- Evaluating vibration as a root cause of failure

Our multidisciplinary approach provides you with diverse perspectives from unique angles.

Our team of scientists, engineers, and technicians can investigate all vibration matters in the field or in the lab, from the component level to the system level, including nanoscale systems.

We have experience with rotating machinery vibration and turbine vibrations, including diagnostics and sensor applications as well as root-cause failure analysis.

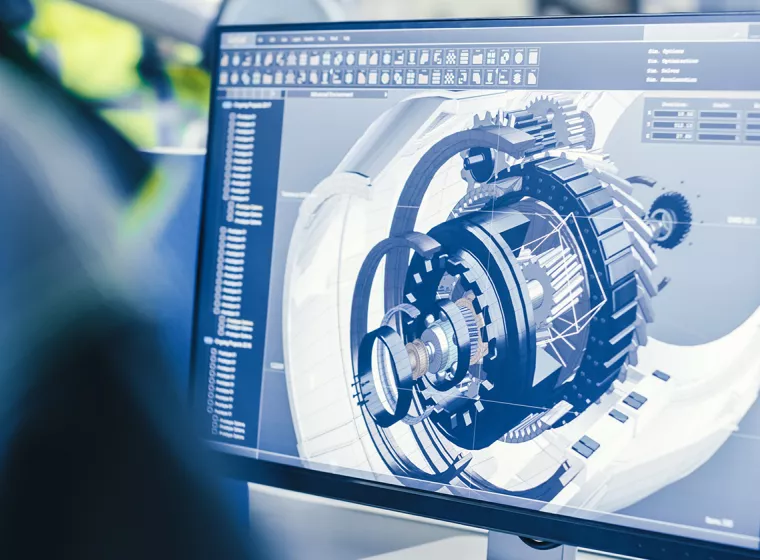

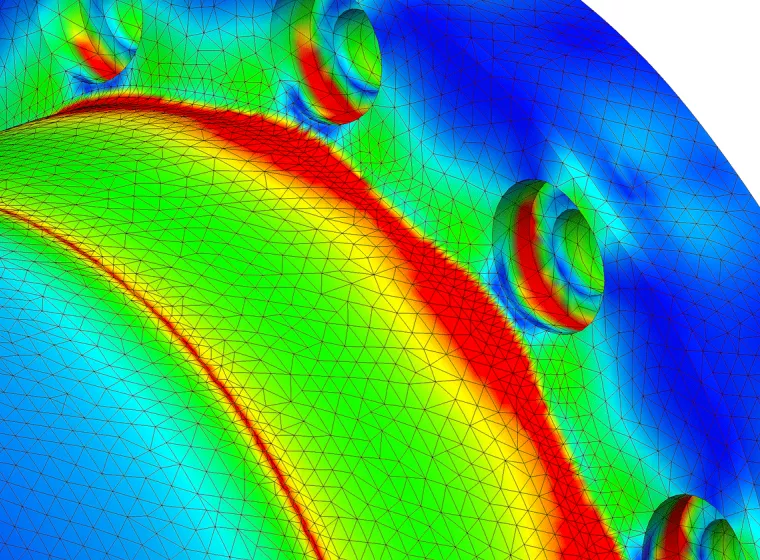

Exponent can analyze the dynamic response of structures using computer-based numerical analysis (including nonlinear finite element analysis) and provide measurements of actual vibration conditions using both contact and non-contact measurement options.

Services

For 50+ years, we've thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Mechanical Engineering Specialties

Mechanical engineering support to help solve complex problems within commercial and industrial applications.

Mechanical Design Support

Mechanical design and testing support services, including customized mechanical modeling, finite element simulations, and system-level testing.

Mechanical Failure Analysis

Discover the root cause of mechanical failure using visual modeling simulation, data analysis, on-site investigations, and laboratory testing.

![Factory Auditing & Assembly Line Evaluations [ME]](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1320492982.jpg.webp?itok=yHRcmsIH)

Factory Auditing & Assembly Line Evaluation

Understand highly integrated automated machinery challenges and mechanical problems across diverse industries.

Risk & Safety Analysis for Mechanical Engineering

Multidisciplinary risk assessments, equipment safety evaluations, and occupational safety analysis.

Mechanical Engineering Support for Dispute Resolution

Mechanical engineering support and testimony for litigation, international arbitration, mediation, and insurance.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Insights

![Vibration & Dynamic Analysis [ME]](/sites/default/files/styles/hero_purple/public/media/images/GettyImages-1255653769.jpg.webp?itok=f8ur4A-0)