How can Exponent provide support for challenges regarding diverse materials including polymers, plastics, batteries, emulsions, and dispersions?

Exponent's multidisciplinary teams focus on innovative ways of assessing and mitigating challenges related to polymeric materials, processes, and products. Our consultants provide technical expertise in organic chemistry, inorganic chemistry, surface and polymer science, and related products and manufacturing systems. For over half a century, we've worked on different types of failures in every industry, and this experience enables us to apply past lessons to innovate better materials for the future.

Multidisciplinary expertise to help you solve complex challenges across a wide variety of industries and applications.

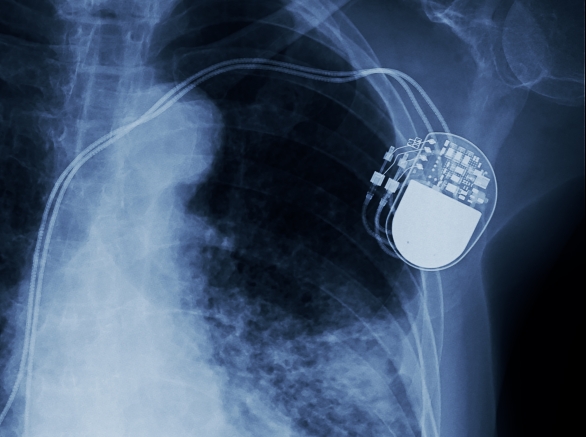

Our broad expertise in physical and analytical chemistry and materials chemistry includes battery science, electrochemistry, plasma chemistry, transport properties, nanomaterials, small molecule compounds, optics, thin-film technologies, and optimization of high-value chemical-based processes. Our engineers and scientists help clients solve challenges related to various battery cell technologies, semiconductors, metal films, dielectrics, polymers, materials processing, catalysis, trace contaminant identification, pharmaceutical process chemistry, medical device materials, and interfacial chemistry.

Capabilities

Our expertise in natural and synthetic plastics, rubbers, adhesives, textiles, coatings, and composite systems includes a fundamental understanding of all aspects of chemistry, structure, processing, properties, and uses. Our multidisciplinary engineers and scientists provide technical expertise that spans a variety of polymeric materials, product forms, formulations, and manufacturing processes across a broad array of industries.