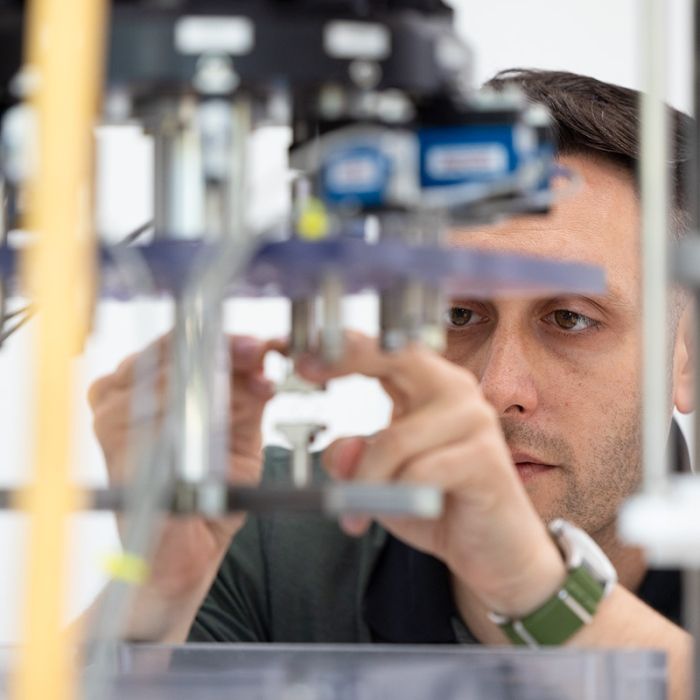

Any Challenge, Anywhere

Quality assurance. Regulatory approvals. Safety assessments. Our experts offer the tools and ingenuity to design and execute advanced custom testing, helping you define the path forward.

Unparalleled Responsiveness

Custom Testing

Client Collaboration

Diverse Expertise

Global Network

Technical Leadership

Time-Critical & Mission-Critical Evaluations

![Battery Supply Chain Services [EECS]](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1411358298.jpg?itok=jO9DbdEZ)

Battery Evaluations

Gain confidence with our cutting-edge evaluations and consulting.

Electric Vehicle Evaluations

Optimize the safety, reliability, and commercial viability of your electric vehicles.

Materials Evaluations

Build a strong foundation for your products with specialized materials evaluations.

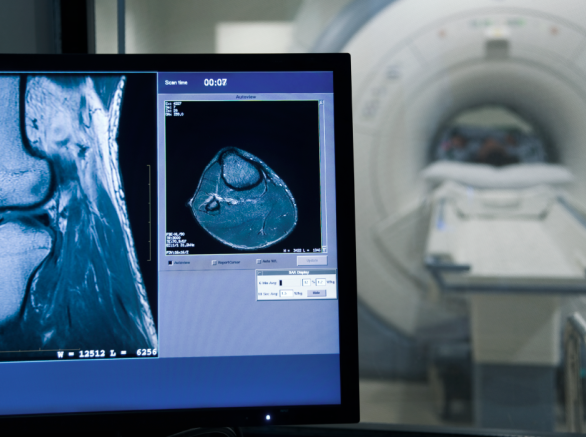

Biomedical Evaluations

Create advanced medical devices and solutions by working with pioneers in the field.

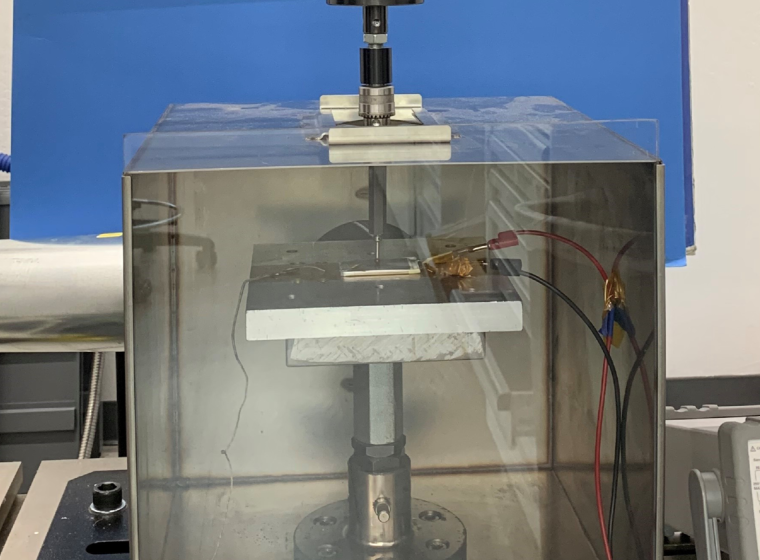

Mechanical Evaluations

Understand your product's strengths and limitations with customized mechanical testing.

Transportation Evaluations

Quantify product performance, analyze system & component failures, and address claims.

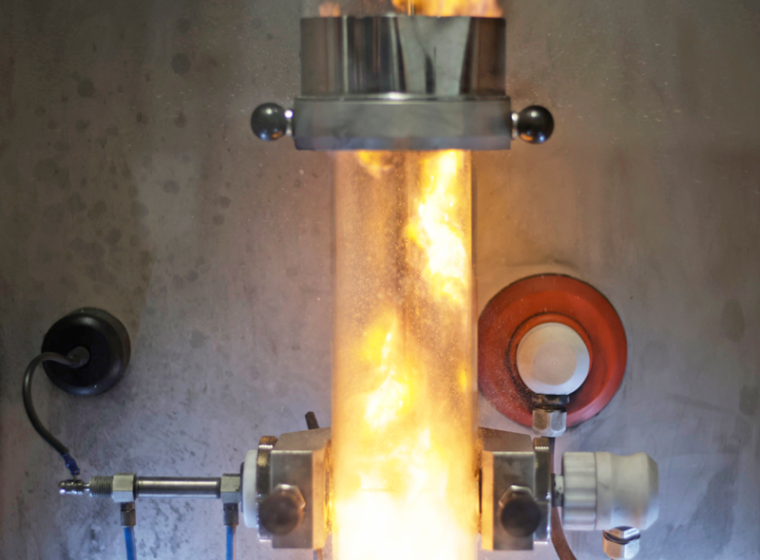

Fire & Flammability Evaluations

Assess fire and flammability risks with custom testing that goes above and beyond the standards.

Intentional Data Acquisition

Collect hard-to-acquire real world data for products that go on or in human bodies.

Exponent UX

Tackle difficult design challenges with user experience research, strategy, and consulting.

Meeting Your Challenges Where They Are

Ensuring regulatory compliance. Evaluating equipment safety. Assessing site surface conditions. Our integrated teams of experts in North America, Europe, and Asia conduct on-site inspections, custom testing, and rapid response for a wide range of challenges. Exponent can also assist with inspections in remote locations through encrypted video-streaming capabilities.

Examine Every Angle

When you work with Exponent, we assemble a multidisciplinary team — from across more than 90 technical disciplines — tailored to your specific challenge. Because getting to the right solution starts with asking the right questions.

Rely on our decades of experience across every major industry to help you move forward in a rapidly changing world.

Insights