June 6, 2023

Exponent's Louis Malito, Paul Briant, Matthew Bowers, Sarah Easley, and Brad James collaborated with Fort Wayne Metals research and development director Jeremy Schaffer to publish "Fatigue, Fracture, and Crack Arrest from Bending Induced Pre-strain in Superelastic Nitinol" in the research journal Shape Memory and Superelasticity.

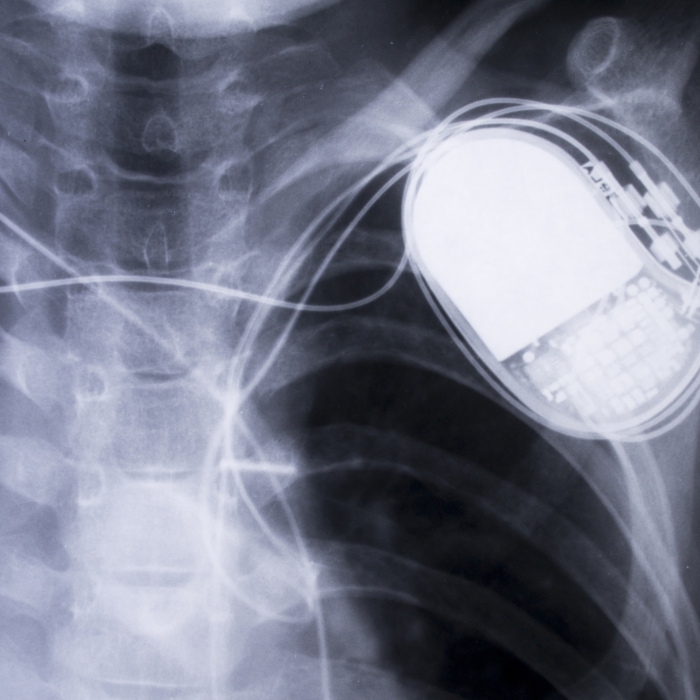

Nitinol-based devices are capable of holding their shape in blood vessels across a service lifetime of hundreds of millions of fatigue cycles, making Nitinol the prevailing material of choice for endovascular and cardiovascular medical device applications. In stents and other medical devices, the highest stresses/strains developed in the device occur when crimping the device onto the catheter and tracking it through the vasculature. This study sought to address a knowledge gap in the literature by specifically investigating the effects of excessive bending crimp/pre-strain on Nitinol fatigue behavior in a vascular device scenario.

Nitinol wire apex specimens were fatigue tested after being subjected to a range of initial bending pre-strains to determine how fatigue performance and crack initiation may be affected by compressive strains and residual stresses developed during crimp. As the crimp strain was increased from 8% to 14.5%, the researchers observed an overall increase in cycles to complete fracture. However, the study also shed light on the complicated relationship between pre-strain and fatigue crack initiation with arrested partial cracks observed in high crimp strain specimens. The results demonstrate that how the pre-strain is applied and how any resulting residual stresses interact with subsequent fatigue loading can significantly affect Nitinol fatigue performance.

The authors note further research is required to elucidate the exact mechanisms of stress and strain that drive crack growth past deceleration or arrest. Their study found that differences in plastic strains developed during the crimp process create residual stresses within the Nitinol that strongly influence whether cracks will initiate or arrest.

"Fatigue, Fracture, and Crack Arrest from Bending Induced Pre-strain in Superelastic Nitinol"

Read the full articleFrom the publication: "Typically, the highest bending stress/strain that endovascular stents and other Nitinol based cardiovascular devices undergo in service occurs during crimping onto the catheter, subsequent device tracking, or sterilization resulting in exposure to high temperatures."