Create safer, more efficient vehicles while remaining compliant with industry and regulatory standards.

For more than fifty years, our multidisciplinary teams have helped the biggest names in the automotive industry develop safer, better-performing, more sustainable vehicles through failure analysis, as well as design and development consulting.

We provide support throughout the entire product lifecycle with the following types of services:

Support for product evaluations

Component and vehicle testing and development

End-use consultation and evaluations, and analysis of component and system failures

Accident investigations, data collection, and reconstruction analyses

Support for manufacturers facing issues of litigation or product recall

Capabilities

Our multidisciplinary teams of experts are leading the future of vehicle engineering with unparalleled accident investigations, robust product evaluations, and state-of-the-art research and testing.

Our accident investigation, product analysis, and research capabilities can help you find answers to your hardest questions.

When you face complex challenges due to allegations of fault related to a specific incident, allegations of product defect or deficiency, or the development of groundbreaking new technologies, Exponent can help.

- We collect product and site data using physical measurements, digital photography, 3D laser scans, and drone (UAV) surveys — often on a rapid response basis.

We perform accident investigations and reconstructions utilizing well-established engineering principles, dynamic modeling-based simulations, animations, and photogrammetric analyses.

We leverage our state-of-the-art laboratories and test facilities to support our evaluations of client products and our investigations into accidents and component or system failures.

Our research and consulting experience and testing capabilities support product evaluations and incident investigations involving:

On-road and off-road motor vehicles

Sport and recreational vehicles

Micromobility devices including e-bikes, scooters, and hoverboards

Construction, mining, agricultural, and industrial equipment and machinery

Municipal transit

Light-rail, commuter, and freight rail

Robust analysis of all types of vehicles and mobile transportation products.

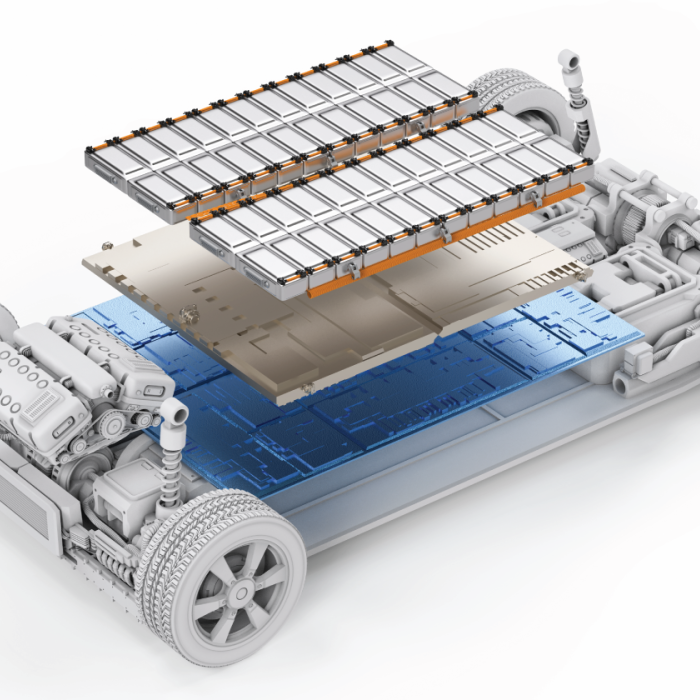

Exponent provides robust analyses of product design, performance, compliance with regulations and standards, and fitness for use. Our consultants evaluate machinery, equipment, and vehicle operator controls; structural crashworthiness; safety systems including ADAS; electrical systems and batteries; and engine, transmission, fuel, braking, and steering systems.

Our multidisciplinary approach addresses the toughest challenges.

Our vehicle engineers collaborate with electrical, mechanical, biomechanical, and materials engineers, as well as data, thermal, and human factors scientists to evaluate all aspects of safety and performance.

By examining every angle and following every lead, we empower our clients with data-driven insights that would not otherwise be identified.

Human factors and biomechanics research & testing.

We incorporate human factors and biomechanical research and testing to quantify human and vehicle system performance and to evaluate the response of the human body to accident forces and accelerations.

We help clients find essential insights and prepare for standards yet to be written with real-world crash testing and driving scenarios.

Our work has scientifically informed industry and national safety policies for over 50 years. With this expertise, we provide:

- State-of-the-art vehicle testing for modern accident conditions

- Extensive evaluations and accident investigations for vehicles equipped with the latest technologies

- Rigorous tests to analyze crash and driving scenarios both at our premier Test & Engineering Center (TEC) in Phoenix, Arizona and in the real world

- Scientific methodology and testing to quantify the response of vehicles, vehicle systems, and human response

- Help answering specific and challenging questions to improve product safety features and performance

Emerging vehicle technology.

For many years, crashworthiness has been the focus of motor vehicle safety research. Exponent has been a leader in this field. Crash avoidance is now at the forefront of vehicle design and safety research. Exponent has invested significantly in our capabilities to scientifically evaluate the real-world performance of emerging vehicle technologies including Advanced Driver Assistance Systems (ADAS), Connected Vehicle Systems (V2X), and Electric Vehicle (EV) systems. We use state-of-the-art robotic vehicle controllers and programmable robotic vehicle and Vulnerable Road User (VRU) targets, which are used to perform repeatable, nondestructive parametric studies and evaluate real-world system performance.

We have developed bespoke test methods to evaluate the response of EV batteries and charging systems under nominal and compromised conditions. We also have unique capabilities to test the behavior of micromobility devices under real-world operating conditions, with operators or operator surrogates (anthropometric test devices — ATDs).

![Automotive [PSMC]](/sites/default/files/styles/fifty_node_cta/public/media/images/GettyImages-154962509.jpg?itok=hHKtcBpc)

![SOFTWARE & COMPUTER ENGINEERING [EECS]](/sites/default/files/styles/filter_content/public/media/images/GettyImages-1341115371.jpg?itok=HpAoCB5K)