May 9, 2025

Expansion of ISO/IEC 17025:2017 accreditation provides third-party validation of biomedical, pharmaceutical, and consumer product test methods

Exponent has expanded the scope of its ISO/IEC 17025:2017 accreditation at its facility in Natick, Massachusetts. The Natick facility has added microbiological testing capabilities to its scope under the American Association for Laboratory Accreditation (A2LA, Certificate #2561.04) for a series of industry standard microbiological methods used to test biomedical, pharmaceutical, and consumer products. In addition, Exponent's Natick facility has added to its accredited capabilities involving both evaluation of the corrosion behavior of medical devices implanted in the human body and evaluation of the safety of laser and optical radiation.

The results from these tests provide clients with critical data that conforms to the rigorous levels of quality assurance required by ISO/IEC 17025. An audit to these requirements allows Exponent to demonstrate that its methods are developed and validated to state-of-the-art, consensus-based, industry standard test methods and conducted using fully traceable equipment.

"With the continuing risk of microbial contamination across biomedical and consumer product markets, manufacturers and regulatory agencies have a strong interest in microbial risk assessments, monitoring programs, and root-cause analysis," said Alexis Sauer-Budge, Ph.D., a principal scientist in Exponent's Biomedical Engineering and Sciences practice. "Our new accreditation to ISO 17025 for microbial analysis conducted in accordance with 21 CFR 58 Good Laboratory Practice for Nonclinical Laboratory Studies is an external validation of our commitment to unwavering quality and excellence in supporting our clients in solving their toughest challenges."

Test methods covered by Exponent's new scope of accreditation

An internationally recognized third-party accreditation body, A2LA performs unbiased, objective assessments of participating labs' quality systems. Exponent's Natick laboratory's accreditation now covers microbial enumeration of non-sterile products to ensure they meet acceptable safety and quality standards, conducted in accordance with 21 CFR 58 Good Laboratory Practice (GLP) for Nonclinical Laboratory Studies.

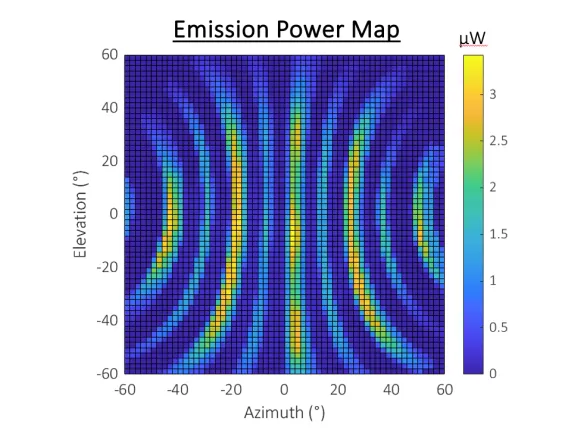

The Natick laboratory's accreditation additionally covers measurement techniques and conditions and safety requirements essential to assessing the emission of laser radiation and evaluating the photobiological safety of lamps and lamp systems, ensuring exposure safety for human eyes and skin.

The accreditation continues to cover a range of electrochemical methods used to assess corrosion susceptibility for biomedical devices and materials to ensure products meet acceptable safety and quality standards.

A summary of the latest accreditations includes:

| Test Type | Test Method |

|---|---|

| Microbiological Examination of Nonsterile Products: Microbial Enumeration Methods | USP <61>1 |

| Cyclic Polarization — Corrosion Susceptibility of Small Implant devices | ASTM F2129 |

| Making Potentiodynamic Anodic Polarization Measurements | ASTM G52 |

| Evaluating the Potential for Galvanic Corrosion for Medical Implants | ASTM G71; ASTM F3044 |

| Cyclic Polarization Measurements for Localized Corrosion, Susceptibility of Iron, Nickel, and Cobalt Alloys | ASTM G61 |

| Determination of Alpha and Accessible Exposure for Laser Wavelengths Between 400 nm and 1100 nm | IEC 60825-1 section 5.4.3 for Condition 3 |

| Photobiological safety of lamps and lamp systems | IEC 62471:2006 |

1 Conducted in accordance with 21 CFR 58 Good Laboratory Practice for Nonclinical Laboratory Studies.

2 Used as a quality control method for the CAB, not used for reporting.

Our Natick laboratory offers cutting-edge testing capabilities in a wide range of areas. Expanding our corrosion and microbiological testing on biomedical materials and devices enables us to answer challenging questions that arise during product development and validation, root-cause and corrective action investigations, and quality control assessments. In addition, our capabilities in the assessment of hazards from optical radiation position Exponent to address evolving safety challenges in the AR/VR, consumer electronics, and automotive industries.