THE CHALLENGE

Over the course of two years, our mining client in the Southwestern U.S. experienced heavy equipment failures that threatened worker safety and cost millions in lost productivity. They turned to Exponent to help investigate the failures at multiple sites.

EXPONENT'S MULTIDISCIPLINARY SOLUTION

Exponent's failure analysis experts worked on multiple projects across the U.S., employing metallurgical and corrosion engineering, mechanical engineering, and thermal sciences expertise to evaluate equipment and infrastructure failures.

Exponent's Impact

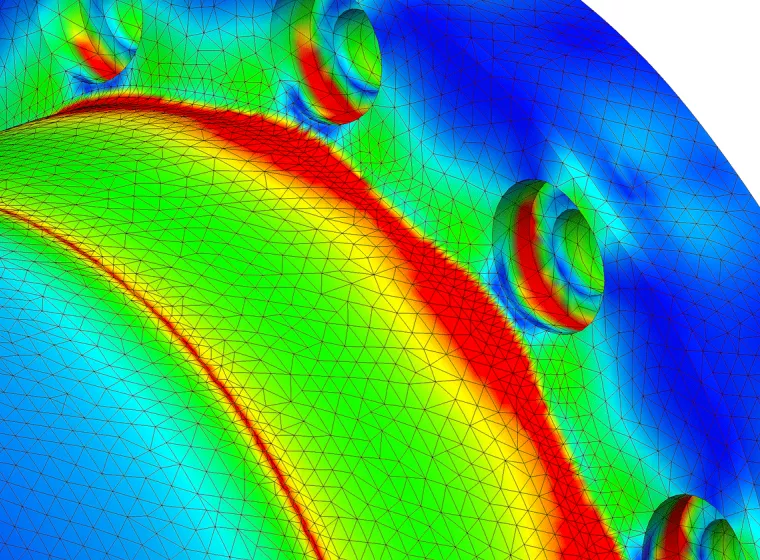

Our metallurgical analysis and inspection findings provided the mine operator with the insights and solutions needed to operate their diverse array of equipment in harsh conditions — including timely feedback and recommendations to mitigate future failures and risks based on our testing results. Our client utilized Exponent's findings regarding fatigue cracking in 6-foot-diameter trunnion bearings to develop inspection protocols across their fleet of bearings and, with Exponent's assistance, detected early-stage fatigue cracking in additional trunnion bearings — preventing costly future failures and enhancing employee safety.

What Can We Help You Solve?

Exponent offers a full range of failure analysis services, from metallurgical and corrosion evaluation to mechanical testing and analysis. Our experts have decades of experience in the mining and heavy equipment sectors and can assess and help rectify many heavy-machinery failure modes.

Failure Analysis

Leading the consulting industry in failure analysis testing and root cause and risk analysis.

Materials, Metallurgy & Corrosion Engineering Capabilities

Assess corrosion risks and follow best practices in materials selection, operations, and corrosion control for metals.

Mining & Forestry

Scientific and engineering expertise to help achieve safe, reliable, sustainable production.

Mechanical Failure Analysis

Discover the root cause of mechanical failure using visual modeling simulation, data analysis, on-site investigations, and laboratory testing.

Mechanical Testing Services

High-quality mechanical testing services in state-of-the-art facilities across the U.S. and internationally.