June 11, 2025

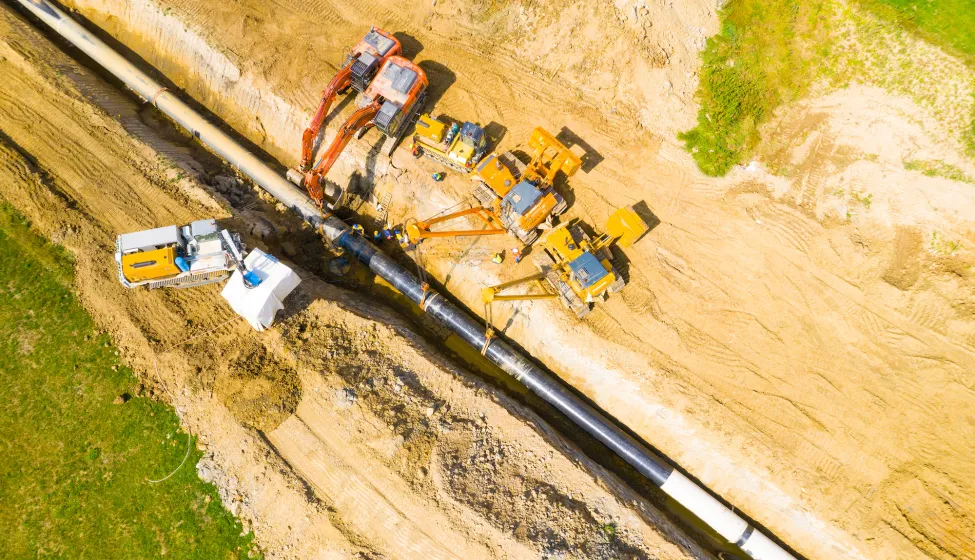

Some vintage electric resistance welded (ERW) natural gas piping is known to contain welding anomalies that can, over time, cause cracking and leakage. Other welding anomalies may be stable and not prone to growth or leakage. Understanding when an anomaly may be prone to leaking over time and when it may be stable is critical for pipeline operators. When performing inspections, integrity assessments, or standard maintenance, indications may be identified and should be analyzed carefully to understand the character of the finding and the associated risk level.

In this paper, Exponent's Alex Hudgins, Ph.D., P.E., and colleagues from Campos EPC, Xcel Energy, and Golden Woods describe an inspection performed on a section of vintage 20-inch natural gas pipeline after workers reported indications. Approximately 83 feet of pipeline was removed for non-destructive and destructive examination and assessment. This effort also included records review, material property characterization, and failure pressure prediction assessment.

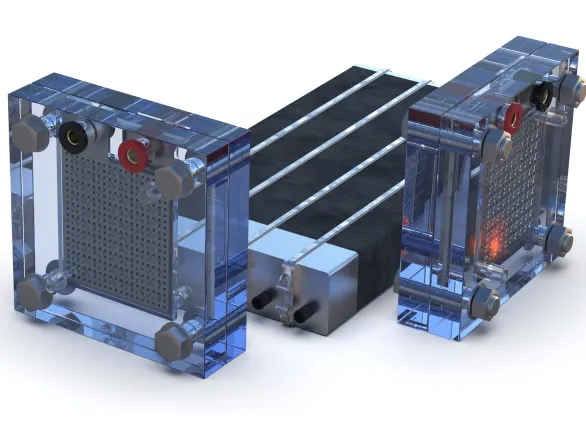

The author team performed magnetic particle testing (MT) and phased-array ultrasonic testing (PAUT) to inspect the seam weld, identifying numerous anomalies in the process. The researchers then used X-ray computed tomography, cryo-fracture, cross-sectioning, metallographic analysis, and scanning electron microscopy in a laboratory to further examine the indications.

"Line Pipe DC-ERW Long Seam Weld Anomaly Investigation"

Access the full article with log-in here

From the publication: "Destructive testing results confirmed observations made by visual observation and NDE suggestion that the indications appeared consistent with electrode (a.k.a. 'roller') contact marks introduced during pipe manufacturing."

Insights