November 18, 2025

Executive Summary

Underground gas storage is playing an increasingly critical role in balancing energy supply and demand as electricity consumption rises and usage patterns become more variable. Aquifers, salt caverns, and repurposed oil and gas wells can provide valuable storage capacity but also introduce complex engineering and environmental challenges. Effectively mitigating these risks demands multidisciplinary expertise in civil and structural engineering, geomechanics, environmental science, regulatory compliance, and more. Rigorous risk assessments and industry best practices — combined with the decades of hands-on investigative experience that Exponent brings to the table — can help stakeholders gain confidence in containment integrity while safeguarding human health and the environment.

Applying advanced technology and deep technical expertise to address unique subsurface storage complexities

As global electricity demand surges — driven by the rapid growth of data centers, electric vehicles, and evolving residential consumption patterns — underground gas storage is becoming an essential tool for balancing energy supply and demand. These storage facilities allow utilities to stockpile natural gas, which currently fuels 43% of U.S. electricity generation, and store hydrogen produced from natural formations or excess renewable energy. This capability helps providers ensure reliable energy delivery during peak periods and manage market fluctuations.

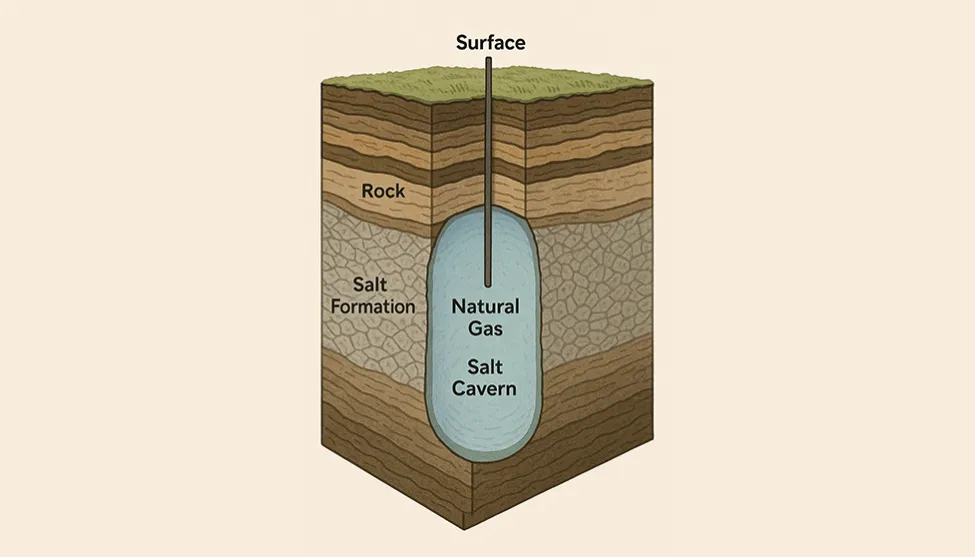

However, realizing the full potential of underground storage poses significant engineering challenges — and risks to human health and the environment when subsurface containment fails. The use of aquifers, salt caverns, and aging oil and gas wells presents formidable technical obstacles, ranging from corrosion and structural integrity issues to gas migration and regulatory compliance.

Successfully navigating these complexities requires multidisciplinary experts — from geomechanical and civil engineers to environmental scientists and data specialists — to conduct rigorous infrastructure evaluations and site-specific risk assessments. This multi-faceted approach is crucial for energy companies and facility operators seeking to enhance containment integrity, improve reliability and safety, and protect surrounding communities and ecosystems.

Where is gas stored and why?

In the U.S., underground gas storage depends on roughly 14,000 active wells, with the majority located in depleted oil and natural gas reservoirs, which account for 80% of total storage capacity (non-potable water aquifers and solution-mined salt caverns account for the other 20%). These sites are chosen for their demonstrated ability to safely contain gas under high pressure, allowing energy companies to store gas during periods of low consumption, such as summer, and release it during periods of high demand, such as winter, when heating and electricity needs spike.

Energy companies are also exploring using underground facilities to store hydrogen, following a "power-to-gas-to-power" strategy. This approach involves converting surplus electricity into hydrogen via electrolysis, storing the hydrogen underground, and then converting it back into electricity — using fuel cells or turbines — during periods of peak demand.

Each storage method — be it depleted reservoirs, aquifers, or salt caverns — presents unique geomechanical and regulatory challenges. These include managing aging infrastructure and pressure cycling in depleted reservoirs, ensuring long-term containment in aquifers, and maintaining the structural stability of salt caverns. Overcoming these challenges demands a broad range of technical expertise, sophisticated evaluation techniques, and customized design and monitoring strategies to maintain well integrity and improve operational safety.

Any compromise in well integrity can endanger nearby communities and ecosystems.

Gas storage wells, depleted reservoirs, and multidisciplinary engineering expertise

Depleted oil and gas production formations are attractive options for underground gas storage, harnessing proven containment structures and existing infrastructure to support energy reliability and grid flexibility. As these assets age, however, corrosion, mechanical wear, and deterioration of casing or tubing systems increasingly impact their integrity, raising the risk of leaks, blowouts, and significant environmental and public health hazards when wells are adapted for gas storage.

Many underground gas storage wells in the U.S. were originally drilled in the 1950s or earlier, making thorough characterization and continuous integrity monitoring critical as they are repurposed for modern energy applications. Any compromise in well integrity can endanger nearby communities and ecosystems, highlighting the substantial risks at every stage of a storage project's lifecycle. Exponent's extensive experience includes root-cause investigations and client assistance in high-profile incidents such as the Grand Bayou salt cavern well leaks in Louisiana and the Aliso Canyon well leak in Southern California. Our work frequently includes custom evaluations and analyses such as the following, although each site can demand additional scopes of technical expertise.

While depleted oil and gas wells provide proven containment structures for underground storage, non-potable (saline) aquifers characterized by their porous rock formations are increasingly being considered as alternative repositories for gas. Unlike depleted reservoirs, however, the geological characteristics of aquifers are often unconfirmed, presenting a distinct set of technical and regulatory challenges. Effective utilization of these formations demands thorough hydrogeological surveys, advanced modeling of subsurface flow and gas migration pathways, and rigorous testing to establish containment integrity and estimate storage capacity. Dynamic simulation models are also essential to predict gas behavior over time. As a result, aquifer assessments are inherently more complex, time-intensive, and costly than repurposing depleted wells, requiring innovative evaluation strategies to support safe, reliable, and sustainable underground gas storage.

Salt caverns and complex geomechanical assessments

Salt caverns are particularly compelling for underground storage because of salt's natural near-impermeability and self-sealing properties. However, these advantages come with unique engineering challenges that demand careful management. Unlike porous, depleted reservoirs, salt caverns are created by solution mining within salt domes — large subterranean formations that develop as salt migrates upward through sedimentary layers. These caverns exhibit complex mechanical behavior, especially under repeated cycles of gas injection and withdrawal.

Many of the subsurface storage considerations relevant to depleted gas wells — such as robust monitoring practices and addressing hydrogen-specific challenges — are also crucial for salt caverns. Additionally, several key technical and application-specific considerations include:

Regulation and permitting

The regulatory landscape for underground gas storage is evolving in response to high-profile incidents and changing energy priorities, reflecting heightened concern over the potential for explosions, hazardous chemicals contaminating groundwater and polluting air, and related risks to human health and the environment. Regulatory updates aim to address these dangers by strengthening safety measures and requiring more rigorous evaluations of well integrity and site-specific conditions.

Federal and state agencies have implemented new regulations governing well design, maximum allowable pressures, inspection frequencies, and safety barriers. For instance, California's Geologic Energy Management Division now requires dual barriers to pressurized gas and mandates frequent reinspection of storage wells, while Louisiana enforces minimum distances between caverns and salt dome edges.

Experience and specialized expertise are essential for navigating these complex regulatory environments and needs, including:

- Regulatory review: Experienced technical experts can assist stakeholders through careful interpretation of evolving or ambiguous regulations, leveraging deep familiarity with specific regulatory bodies to offer tailored guidance.

- Risk assessments: Multidisciplinary experts help stakeholders conduct risk assessments and prepare technical reports supporting complex regulatory applications for new storage projects or modifications to existing facilities.

- Site-specific design considerations: Experts in gas production well and salt cavern assessments may, depending on site-specific conditions and other factors, recommend more frequent logging, enhanced corrosion protection, or other measures beyond minimum standards to further mitigate risk and address operational efficiency.

- Stakeholder engagement: Addressing public concerns about environmental impacts, especially with new technologies like hydrogen, requires clear communication and proactive regulatory engagement. Experienced consultants can help bridge communication between stakeholders and regulators.

Additionally, acquired technical and regulatory knowledge from natural gas and hydrogen storage heavily informs evolving opportunities, like carbon capture and sequestration (CCS) — a pivotal technology that also relies on subsurface containment. While CCS shares challenges like well integrity and geomechanical stability in reservoirs or caverns, it requires stricter controls and long-term monitoring as carbon dioxide is injected for permanent storage.

Regulations are changing quickly, with new well classes for carbon dioxide storage and increased monitoring requirements. Successful CCS projects can leverage several of the methods applied in underground gas storage projects — including rigorous integrity and corrosion evaluations, advanced modeling, and proactive regulatory coordination. Bespoke risk assessments are critical to address temperature and pressure variations, supporting the selection of customized materials and pipe designs that safeguard against potential failures, environmental hazards, and costly operational disruptions, following the same tenets to promote long-term integrity and subsurface storage safety.

Frequently Asked Questions

What Can We Help You Solve?

With unparalleled industry expertise, Exponent's multidisciplinary experts can help clients developing or upgrading underground gas storage or CCS facilities balance operational efficiency with robust safety strategies. Our geomechanical and environmental engineers offer wide-ranging regulatory support, advanced modeling capabilities, and bespoke technical risk assessments to prioritize safety, sustainability, and innovation.

Power & Energy

Multidisciplinary support for high-power energy systems of all sizes in a variety of applications.

Pipeline & Process Piping

Mechanical engineering expertise for pipeline construction, pipe corrosion, pipeline integrity management, and pipeline failure analysis.

Structural & Geotechnical Quantitative Risk Assessment

Innovative, quantitative risk assessments to support climate-change planning that helps protect buildings, infrastructure, and other valuable assets.

Mechanical Engineering

Rigorous failure analysis, risk assessments, and auditing of mechanical systems in every industry.

Environmental Forensics

Determine and remediate contaminant sources accurately and effectively with precise science and technical expertise.

![[MCE] Factory Auditing & Assembly Line Evaluations - view of assembly line floor](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1320950393.jpg.webp?itok=JflDDR6c)

Materials & Corrosion Industry Expertise

Materials science engineering expertise tailored for every industry.