January 20, 2022

Cosmetic imperfections may signal larger manufacturing problems

Manufacturing defects cost the industry an estimated 10-20% in lost revenue each year, and this doesn't include consumer health, business reputation, and other nonquantifiable costs. These defects are often caused by assembly errors, faulty manufacturing equipment, poor raw material quality, or other issues that may have been exacerbated by line shutdowns due to COVID-19 or ongoing supply chain disruptions.

Like all manufacturing defects, cosmetic blemishes can occur anywhere in the product development process — from initial planning, design, validation, to the mass production stage — and affect a wide range of finished products, including electronics, chemicals, polymers, packaging materials, cosmetics, pharmaceuticals, medical devices, and construction material. While scratches, cracks, dents, misalignment, corrosion, stains, discoloration, and other cosmetic defects often don't prevent the product from performing according to requirements, not all cosmetic defects are benign.

Take, for instance, cosmetic blemishes in the coating of implantable medical devices. If there is a crack or hole in the coating on an implantable medical device, metallic ions from the device could leak into the body of the patient with adverse health effects.

Manufacturing Defects

Some cosmetic imperfections not only affect the short- and long-term performance, reliability, and quality of a product but may also indicate larger systemic manufacturing problems, leading to plant shutdowns, product recalls, and regulatory noncompliance.

The longer such imperfections remain unaddressed, the more difficult and resource intensive they become to resolve. While the manufacturing industry has made tremendous efforts in troubleshooting such imperfections, the detection, identification, and selection of the right corrective approach remain challenging.

The cost of imperfection

Cosmetic failures are costly and can not only result in the loss of reputation and sales for manufacturers but can also increase costs through the material wasted in producing defective products, the time lost in reprocessing defective products, returned materials, and warranty recalls. A defect that is symptomatic of a larger problem, such as contamination in the manufacturing process, can lead to an expensive production line shutdown.

Although manufacturing failure rates vary depending on sector, the failure rate across the globe is estimated to be around 75 parts per million. Improving the failure rate requires a large investment in time and resources for troubleshooting to identify the cause of the problem. There's also the cost of preventing defects by examining the performance of products and processes to ensure conformance with requirements.

Early detection of defects can reduce expenses, save time, and boost consumer confidence, as a medical device company working with our team found out by correcting a cosmetic defect early in the design phase. The company was designing a patch to monitor vital health statistics as people exercised. Dark spots began appearing on the cover of the device that didn't affect the function but had the potential to affect human health.

Devising a litany of specialized tests, our chemical regulation and in-house toxicology experts evaluated the health effects of all the chemicals in the dark spots and determined that they could cause a skin allergy if the component they were leaking from was not secured.

By altering the design and sealing the component in place, the company was able to make changes in the initial design phase that prevented larger financial and consumer health losses that would have ensued had the flaw not been found and corrected early in the process.

Perfecting your product and process

Eliminating cosmetic defects can be a multifactorial challenge that often involves supply chain, manufacturing processes, materials, and human error, requiring in-depth knowledge in a broad array of fields, including polymers, chemistry, materials science, and mechanical and corrosion engineering.

With the right team and tools, improving the manufacturing production process and product quality can be cost-effective and time-efficient. For instance, when a portable electronics company was experiencing delamination (the loss of coating adhesion between the glass and device frame) in one of its products during assembly, we employed methods from a broad range of fields to test a variety of hypotheses regarding the cause of the defect.

Using chemical analysis, mechanical strength, thermal expansion, and finite element analysis tests, we determined that the delamination originated from excessive stress applied on a screw near the corner, causing the frame to gradually yield under the pressure and allow moisture to degrade the components. Allowing more room around the screw for stress release solved the problem, which could have led to serious electronic failure and reliability issues.

Failure analysis is another important aspect of eliminating cosmetic defects and identifying improvements to help prevent future failures. A failure investigation includes determining the root cause of a cosmetic defect by examining the composition and application of the product and selecting testing based on this examination to identify the cause of the defect.

For example, we performed an onsite inspection at a vacation resort of the composition and application of a double-paned glass wall that developed dark stains on its inner layer two years after its construction. Our inspection, combined with our chemical analysis and simulation testing, proved that the stain was caused by humidity trapped between the glass wall's two layers, which had not been sealed correctly to create a vacuum. We were able to recommend that the manufacturer add a clear water-proof layer on the glass to increase the longevity of the glass.

Besides onsite inspections, audits are also useful for defining the problem, collecting data, separating causes from symptoms, determining corrective action, implementing the solution, and validating and extending the results. They can also help to evaluate current quality performance and identify opportunities for process improvements.

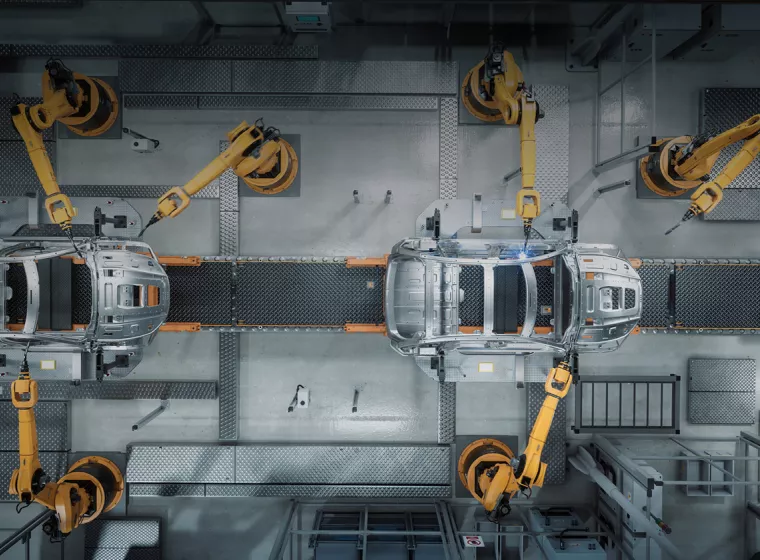

Additional methods for rooting out defects include "Smart Manufacturing" technologies. Computer modeling or simulation programs can detect problems early in the manufacturing process by enabling manufacturers to simulate production scenarios and test their products in a safe and cost-free environment. The use of intelligent visual inspection systems can also help ensure high product quality by performing a range of defect detection tasks.

How Exponent Can Help

Exponent has extensive experience helping clients throughout Asia and the United States develop strategies to improve their manufacturing processes and performance. Drawing on expertise in polymers, chemistry, materials science, mechanical and corrosion engineering, and other fields, our team has a thorough understanding of several ISO quality and auditing standards to help ensure best practices in manufacturing.

In addition to full factory assessments, Exponent frequently visits manufacturing lines as part of our root-cause analysis investigations and materials science-based characterizations. This includes examining the manufacturing process to understand how contamination, mechanical defects and deformation, tolerance errors, and physical and chemical control parameter settings may have contributed to defects.

What Can We Help You Solve?

Industrial & Manufacturing

Exponent's multidisciplinary teams can help industrial & manufacturing clients optimize efficiency and minimize risk.

Manufacturing Audits

Technical products and systems evaluations aligned to Exponent's thorough understanding of ISO quality and auditing standards.

Polymers Expertise for Consumer Products

Rigorous testing and analysis of polymers in consumer products.