August 5, 2025

Executive Summary

Rising demand for critical minerals like rare earth elements is driving rapid growth in the mining sector, which comes with the risk of project delays, cost overruns, accidents, and equipment failures. Exponent empowers stakeholders in the critical minerals mining sector with rapid, multidisciplinary failure analysis to minimize downtime and financial loss following incidents. By leveraging advanced tools like DEM, CFD, FEA, and NDT, Exponent delivers precise root-cause insights and litigation-ready expertise that clarify complex technical failures. Our proactive risk management strategies help clients strengthen operational resilience, reduce future disputes, and thrive amid accelerating global demand.

How can stakeholders best respond to accidents and failures and mitigate risk in today's rapidly changing mining environment?

Critical minerals, including rare earth elements, are fundamental building blocks in the modern economy, used in batteries and electronics, medical devices, renewable energy applications, defense systems, and more. Governments around the world are accelerating critical minerals mining projects and securing international agreements to diversify their supply chains and support innovation.

In March 2025, the U.S. fast-tracked approvals for 10 domestic critical minerals mining projects. Since 2021, the EU has taken a similar approach, streamlining the permitting and financing processes to spur critical minerals mining in Member States alongside negotiating 14 strategic critical materials partnerships. Overall, the demand for critical minerals is expected to more than double by 2030 and triple by 2050.

As new mining sites and heavy equipment come online around the world, incidents ranging from occupational injury to equipment breakdowns to issues with infrastructure, such as roads, walls, tunnels, tailing dams, processing plants, and more, can all mean steep financial losses and downtime. To help limit the impacts of mining claims, qualified technical experts can respond rapidly to assess what went wrong and help mitigate risks and prevent future incidents.

With potentially billions of dollars at stake in mined minerals and the heavy industrial equipment used to unearth them, stakeholders can prepare now for how they will react when an incident occurs and integrate key lessons into future operations.

If an incident proceeds into litigation or arbitration, it's equally important to have highly qualified and experienced failure analysis experts who can support the full process, including the ability to clearly explain technical concepts to judges, juries, and other finders of fact.

Why is rapid response so important?

When a mining incident occurs, the initial discovery phase is foundational to downstream investigative efforts. By arriving quickly on the scene of a failure or accident, failure analysis teams can move to preserve crucial evidence, document the scene conditions, and advise on appropriate next steps.

Mining site owners and operators can expect a rigorous investigation to include thoroughly documenting the scene and related equipment; gathering measurements, photographs, and physical evidence; surveying witnesses and available video footage; analyzing data from equipment and sensors; reviewing records related to the mining site; and, depending on the site and failure, evaluating various geological and geotechnical factors. Assessing an incident at a complex mining site can require a variety of multidisciplinary experts, such as civil, structural, materials, electrical, mechanical, environmental, and thermal engineers, as well as health, human factors, and data scientists, among others.

Rapid deployment of highly specialized experts can prove transformative in scenarios where representatives from regulatory bodies such as the U.S. Mine Safety and Health Administration (MSHA) have initiated an on-site investigation. In such cases, independent failure analysis experts can accompany MSHA or other regulatory agents, gaining a valuable, firsthand view of the incident scene while offering insights and investigative strategies — factors that can have a direct impact on a dispute outcome. If an incident proceeds into litigation or arbitration, it's equally important to have highly qualified and experienced failure analysis experts who can support the full process, including the ability to clearly explain technical concepts to judges, juries, and other finders of fact.

Exploring advanced approaches to root-cause analysis

After analyzing the failure on site, a thorough root-cause analysis will typically follow. This process can include deploying advanced methodologies that help answer key questions in a complex, multifactor investigation involving people, processes, heavy equipment, operating requirements, infrastructure, and any number of anomalies that may have contributed to the circumstances. For example, a conveyor belt or hydraulic equipment failure could be the result of corrosion, material fatigue, inadequate material choice, maintenance challenges, excessive loads, or a design flaw — or a combination of all the above. Having the right capabilities in place can create clarity around root causes while also ruling out unrelated factors.

- What is discrete element modeling (DEM)? DEM is an advanced computational technique that simulates the motion, contact forces, and breakage of granular materials and other particulate systems by simulating the physics of each individual particle. For example, for a ball mill or rock crusher, DEM can predict particle size evolution and power draw.

- What is non-destructive testing (NDT)? Ultrasonic testing (UT), dye penetrant testing (PT), and X-ray computed tomography (CT) are all types of NDT that enable characterizing the condition of components without causing physical damage. This can be critical in situations where altering the state of the mining components could compromise the integrity of the analysis or future operation.

- What are computational fluid dynamics (CFD)? CFD is a technique used to analyze and simulate fluid flow within slurry pumps and other equipment to identify issues that may have caused pressure drops, flow distribution issues, or erosion. CFD can be implemented in the context of mining accidents and, more broadly, risk management.

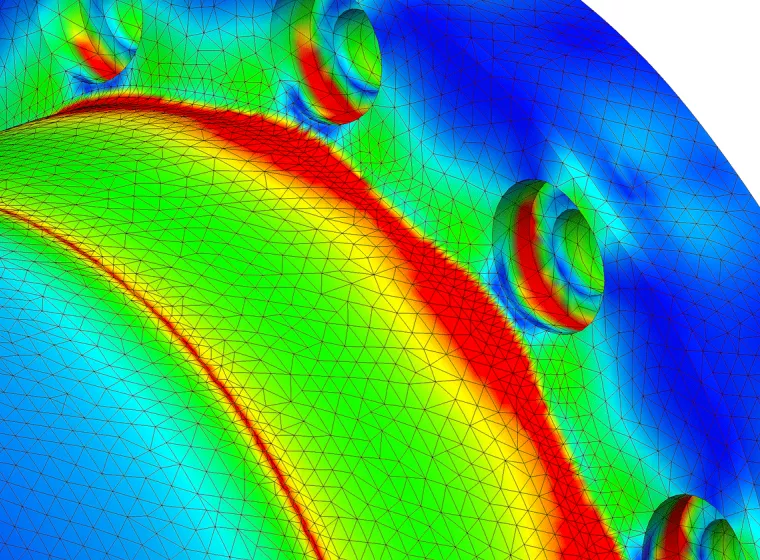

- What is finite element analysis (FEA)? FEA is a computational method that entails the breakdown of complex objects or equipment into simpler elements. FEA allows for analysis of equipment behavior under various load conditions, heat, and vibration, which may impact structural integrity and contribute to failure.

Just as these tools can help rule causal factors out, they can also be used in combination to corroborate results. For instance, in a dispute involving a slurry pipe failure or the splitting of a tailings pipe, CFD can be combined with DEM to provide critical insights around whether over-pressurization, accelerated wear, corrosion, or other factors led to a jam or failure. DEM experts can apply this technique to mining incidents involving bulk materials, such as ore or gravel, within rock crushers and other equipment and to phenomena like flow, mixing, and comminution of granular materials, providing a level of analysis distinct from the capabilities of FEA alone.

Stakeholders leveraging advanced analytical tools should bear in mind, however, that not all tools are equally capable of delivering comparable results. Computational analysis is a rapidly evolving field; users of these tools will benefit from careful expert analysis to ensure they are leveraging technologies that represent state-of-the-art capabilities.

A comprehensive approach to risk management helps organizations thrive as they rapidly scale to meet global demand for these vital materials for the world's economic and technological needs.

How do failure analysis teams guide corrective actions and risk management?

Through the lens of objective and accurate root-cause analysis, an expert failure analysis team should be able to make insightful suggestions about how to mitigate future risks to equipment and personnel. Experts can leverage the same advanced analytical techniques used to diagnose mining incidents to implement corrective actions and establish robust risk management practices that help prevent future incidents and disputes.

FEA conducted as part of an accident investigation, for instance, can support conveyor or crusher design improvements and validate structural integrity under various operational scenarios. Likewise, CFD can guide modifications in slurry pipes and other fluid handling systems to enhance performance and reliability, and DEM can be used to optimize design and operational parameters for ball mills and other essential equipment, reducing wear and improving efficiency.

One in-the-field example of expert failure analysis producing proactive risk management measures resulted from Exponent's investigation of a mining client's ball mill failure. The failure involved the through-wall cracking and separation of an 8-foot diameter bearing, the collapse of the mill (which continued rotating), and material damage and fire.

Through on-site inspection, materials testing, and laboratory analyses using a scanning electron microscope, Exponent's materials and mechanical engineering experts determined that the accident was the result of material fatigue. Through this work, Exponent provided recommendations for important corrective actions, such as the use of fluorescent dyes during scheduled mill shutdowns and routine inspections to identify any fatigue cracks that may be present across the fleet of ball mills. Ultimately, these measures helped our client identify additional subcritical fatigue cracking, replace at-risk components, bolster the resilience of their equipment, and increase operational reliability.

What are some additional risk management considerations?

As the critical and rare minerals mining industry continues to evolve, staying ahead of failures and preparing now to respond to potential disputes is key to mitigating future risk and maintaining operational continuity. Proactive mine operators will also find that beyond rigorous risk assessments, predictive analytics and modeling, and the use of advanced sensors and other monitoring technologies, they can minimize downtime and improve on-site safety and reliability through regular inspections, preventative maintenance, component replacement, operational and hazard identification training, and clear and effective emergency response protocols. A comprehensive approach to risk management helps organizations thrive as they rapidly scale to meet global demand for these vital materials for the world's economic and technological needs.

Frequently Asked Questions

What Can We Help You Solve?

With decades of experience supporting mining operations, Exponent offers clients breakthrough insights and unmatched expertise in advanced analytical techniques to perform root-cause failure investigations. Our mining industry experts leverage our state-of-the-art laboratories to deliver rigorous evaluations, host inspections in disputes, and provide objective, independent court testimony.

Environmental Forensics

Determine and remediate contaminant sources accurately and effectively with precise science and technical expertise.

Corrosion Science & Technology

Breakthrough insights for all types of corrosion and environment-related degradation challenges.

Mechanical Failure Analysis

Discover the root cause of mechanical failure using visual modeling simulation, data analysis, on-site investigations, and laboratory testing.

Process Safety Hazards & Risk Analysis

Thermal science expertise to help you Identify hazards, mitigate risks, and improve safety and compliance with regulatory practices

Environmental Engineering

Objective evaluation to help prioritize resources for cost-effective, compliant environmental remediation.

Metallurgical & Corrosion Engineering

Valuable insights for your most formidable metallurgical and corrosion engineering challenges.