February 10, 2026

Executive Summary

Helmets may look simple, but designing them takes careful work in materials science, mechanical engineering, and biomechanics, all focused on protecting the head and brain. Advances in helmet design and testing have led to major reductions in head injuries. Research shows that wearing a helmet can reduce the risk of head injury by up to 60% for cyclists and nearly 70% for skiers.

Helmets used in recreational activities like cycling and skiing must meet demanding expectations and comply with stringent safety standards. They need to protect wearers, be comfortable and easy to use, and perform reliably in real-world crashes. When helmets fail to prevent or mitigate injury, understanding why is critical. That knowledge helps manufacturers assess designs, supports safety compliance, and informs investigations involving injury and liability.

The Science of Snow Sports Helmets

In a special episode of CBS's Mission Unstoppable Feb. 21, 11 a.m. EST, Exponent's Jessica Isaacs, Ph.D., P.E., and Lisa Lallo, Ph.D., P.E., CPP, take viewers inside the science behind snow sports helmets. Through hands-on demonstrations and biomechanical experiments using crash test dummies, they explain how helmets are designed, tested, and evaluated to reduce injury risk. The episode also provides an opportunity for families to talk with their children about helmet safety and how science helps keep people safe.

Materials that Protect

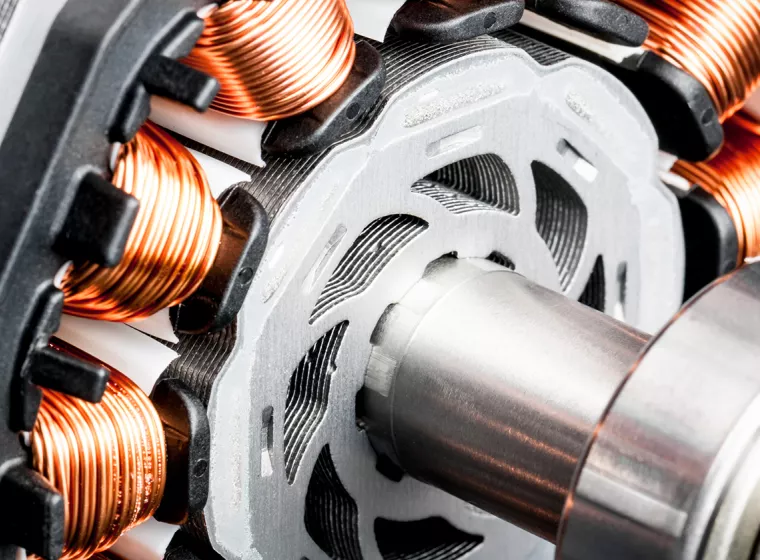

Modern helmets are made from multiple layers of materials, including energy-absorbing foams, plastics, and gels, designed to deflect, absorb, and distribute forces during impact, slowing down the forces transferred to the head and brain. These materials have undergone extensive testing and analysis at the component level before being assembled into a helmet design, which includes compression testing to measure energy absorption and microscopic analysis to characterize structure-property relationships of the materials. Chemical testing helps ensure that sweat, sunscreen, and moisture do not degrade the materials. Artificially accelerated aging can also be used to simulate exposure to sunlight, heat, and cold to evaluate the effects of environmental factors on helmet components.

How do engineers design, test, and improve helmets to reduce head injury risk in snow sports and beyond?

Standards and safety testing for helmets

Helmets meet rigorous safety standards and guidelines set by organizations such as ASTM International, the U.S. Department of Transportation, the Consumer Product Safety Commission, the European Union, Snell, NOCSAE, and others. These standards include tests for impact, puncture resistance, retention, and fit. Snow sports helmets can face higher-speed impacts than road cycling helmets, so testing is adapted to the environment where the helmet will be used.

Testing often involves dropping helmets onto anvils of different shapes and measuring forces with sensors. Retention systems such as straps are also tested to help ensure that the helmet stays securely on the wearer's head during a crash. These tests allow manufacturers to meet safety standards and give consumers confidence in their protection.

Different helmets for different hazards

Helmets are not one-size-fits-all. Different activities expose users to different impact scenarios, force directions, environments, and use conditions. As a result, helmet designs vary based on their intended application and the specific conditions and injury mechanisms associated with an activity.

Rock climbing, mountaineering, and caving helmets, for example, prioritize protection from falling objects and repeated low-energy impacts from above. Arborist helmets and industrial hard hats are similarly designed to protect against overhead impacts but also penetration and workplace hazards, with some designs addressing side and rear impacts as well. Electrical safety helmets incorporate insulating materials to reduce electrical risk while maintaining impact protection. Aviation helmets, particularly those used by rotary-wing pilots, are designed to provide impact protection in crash scenarios while integrating communication systems and noise attenuation.

Snow sports helmets are designed for cold environments and higher-speed falls on snow and ice, balancing impact protection, ventilation, and comfort.

Biomechanics and human response

Understanding how the human body responds to forces is critical to helmet design. Anthropomorphic testing devices (also known as "crash test dummies") mimic human size, mass distribution, joint characteristics, and mechanical response to loading. They are equipped with sensors to track acceleration, impact, and stress during simulated crashes.

By combining material testing with biomechanical analysis, engineers can quantify how helmets reduce forces on the head and brain. Wearable sensors and computer simulations complement this research by providing data from real-world scenarios, helping to re-create accidents and better understand injury mechanisms.

This combination of engineering and biomechanics helps ensure that helmets are not only tested to withstand impact but are designed to minimize injury in realistic conditions.

How helmet technologies are evolving

Helmet safety is not just about wearing protective gear but about understanding how helmets work, knowing their intended use conditions and limitations, and appreciating the ways the industry continues to evolve. Despite decades of research and development and numerous design improvements, helmets are not invincible. For example, a helmet that has been involved in an impact event may need to be replaced, as the energy-absorbing foam is designed to permanently deform and may not provide the same level of protection as the as-manufactured helmet.

Snow sports helmets are sophisticated products born from the intersection of engineering, materials science, and biomechanics, but ongoing research and testing continue to refine their design. By studying materials, human responses, and real-world conditions, Exponent researchers are contributing new insights for injury prevention and product development to the science that helps save lives on slopes and trails around the world.

What Can We Help You Solve?

Exponent's engineers and biomechanics experts test and analyze sports safety equipment, including helmets, pads, and clothing. Our consultants evaluate materials at a microscopic level to determine how they perform and test complete helmets and other equipment to help ensure they keep users safe.

Biomechanical Expertise for Product Evaluations

Biomechanical risk evaluation for products ranging from consumer and recreational products to industrial equipment and vehicles.

Biomechanical Engineering Support for Product Design & Development

Biomechanics product design analysis for a range of applications — from apparel to consumer products to wearable sensors to vehicles.

Biomechanical Testing & Modeling

Uncover the root cause of injuries with robust and advanced biomechanical analysis.

Mechanical Engineering

Rigorous failure analysis, risk assessments, and auditing of mechanical systems in every industry.

Testing & Evaluations

Access a global network of testing and evaluations facilities 24/7 that brings together Ph.D. experts, tools, and technologies for your unique challenges.

Biomechanics

Breakthrough biomechanical insights to inform product or program development.