How does Exponent's multidisciplinary approach provide breakthrough insights for factory processes and product quality?

Exponent conducts factory and assembly line evaluations to help clients proactively improve processes and help provide an understanding of product failures and other challenges.

Our materials engineers work closely with multidisciplinary teams — comprised of mechanical and electrical engineers and polymer and data scientists — to analyze adhesion, molding, and surface treatments, as well as evaluate contamination, air quality, and assess quality control measurements in the production environment.

Through our proactive audits, we can provide support for materials and manufacturing partner selection as well as analysis on how to improve the performance of combination products.

Proactively identify vulnerabilities within your facilities, processes, and materials to mitigate failure, decrease rework, and increase value to your end user.

While our engineers have a strong background in ISO 9001 auditing techniques and principles, our knowledge of how products fail in the field and how the manufacturing process can contribute to such failures provides unique value for factory audits. We focus our audits on manufacturing processes — finding the root of the manufacturing problem and identifying potential problems before they arise — rather than on the quality system associated with the process.

Our on-site investigations provide a deeper understanding of the challenge and help identify root causes.

Exponent frequently visits manufacturing lines as part of our root-cause analysis investigations. After examining failed products and identifying causes, we examine the manufacturing process to understand what role, if any, various manufacturing and handling processes could have played in the failure, including contamination, mechanical defects and deformation, tolerance errors, and physical and chemical control parameters.

Additionally, Exponent engineers support developing quality process audit (QPA) documents to facilitate vendor and supply chain management programs.

Capabilities & Services

Exponent conducts factory audits for diverse industries, processes, and products and offers a wide range of factory auditing and assembly line evaluation services.

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

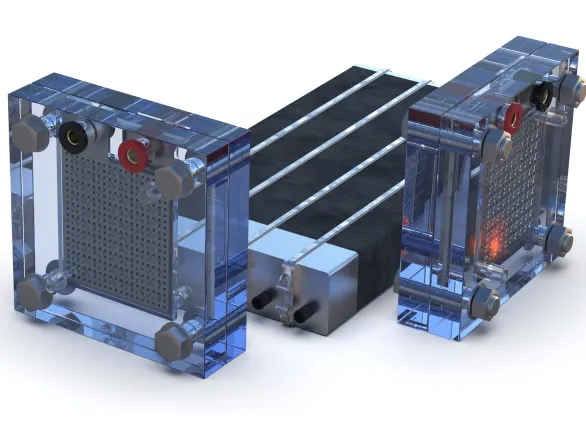

Batteries & Energy Storage

Supercharge performance, reliability, and safety across all stages of the battery and energy storage product lifecycle.

![[MCE] Factory Auditing & Assembly Line Evaluations - view of assembly line floor](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1320950393.jpg.webp?itok=JflDDR6c)

Materials & Corrosion Industry Expertise

Materials science engineering expertise tailored for every industry.

Product & Process Advisory

Materials and corrosion engineers assist with materials issues at every stage of your product or process lifecycle.

Materials, Metallurgy & Corrosion Engineering Capabilities

Assess corrosion risks and follow best practices in materials selection, operations, and corrosion control for metals.

Materials & Corrosion Engineering Expertise for Disputes

Technical scientific support for disputes involving materials and corrosion.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Director of Asia Offices and Principal

Insights