Evaluate asset and operational risks throughout your asset lifecycle.

While oil and gas pipelines are one of the safest ways to transport natural gas, crude oil, and refined petroleum, they still present several safety challenges, including the potential for leaks and spills.

Exponent's multidisciplinary teams have analyzed a myriad of oil and gas pipeline failures using both traditional and innovative situation-specific methods.

We apply 50+ years of experience in failure analysis to help make the future safer and more sustainable.

Our materials and corrosion engineers work collaboratively with other subject matter experts to analyze pipeline time-dependent and time-independent threats such as seam weld defects, internal and external corrosion, and many others. Threats can exist throughout an asset's lifecycle, and Exponent can help connect deterministic, detailed integrity analysis with high-level, programmatic asset management.

Our state-of-the-art testing labs, equipment, and proven methodologies provide insights for better decisions.

We leverage state-of-the-art testing in our on-site labs, computational analyses, and industry understanding to evaluate failures, extent-of-condition, and fitness-for-service of specific pipeline issues, providing evidence-based information to help you make better operational and business decisions.

We have a broad scope and breadth of experience implementing quality management systems across industries.

We have extensive experience developing and implementing quality management systems across many industries and have successfully developed quality programs for the oil and gas industry.

We also work closely with our clients to rapidly respond to corrective action requests issued by regulatory agencies, including the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA), and the Environmental Protection Agency (EPA). We work with both the public and private sectors, providing engineering management and environmental and health consulting.

Summary of Services

For 50+ years, we've thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

Insights

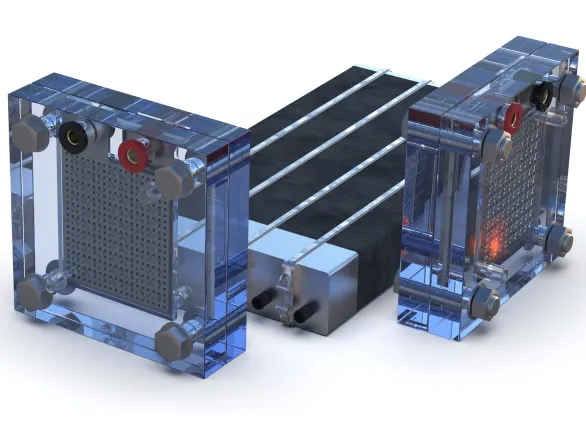

The Electrolyzer Boom

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President and Principal Engineer

Practice Director and Principal Engineer

Senior Managing Engineer