How does Exponent's Materials & Corrosion Engineering team provide an objective understanding of materials challenges?

Failure analysis is the process of collecting data, developing hypotheses, testing hypotheses, and analyzing everything to determine the cause of a failure. We apply lessons from past failures across industries to help make the future safer and more sustainable. From energy to electronics to medical devices to systems and controls — understanding of materials failures is critical to ensuring product and process safety.

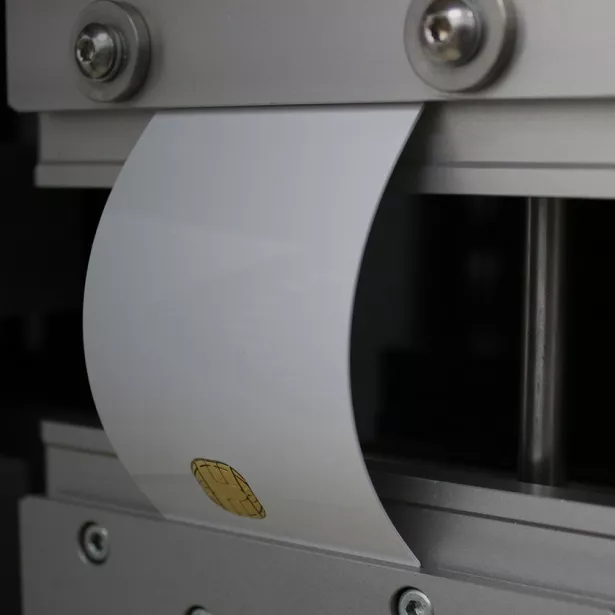

At our global labs, Exponent's multidisciplinary teams combine rigorous testing applications and methods — from Computed Tomography (CT) scanning to X-ray imaging and microscopy. However, the differentiated value that we deliver is unparalleled evaluation and analysis capabilities, resulting in evidence-based insights for better business decisions at every point in your product or process lifecycle.

Our methodology

- Problem Definition:

- Systematic definition of inputs to reduce total troubleshooting time

- Identification of inputs via production experience and engineering judgment

- Identification of Correlations:

- Searching for values or a combination of values associated with the failure or defect

- Applying troubleshooting experience to achieve efficient, cost-effective searching

- Validation:

- Recreation of the failure to confirm causation

- Augmenting organizational knowledge through sharing success and documenting lessons learned

Summary of Services

For 50+ years, we've thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President and Principal Engineer

Practice Director and Principal Engineer