How does Exponent's multidisciplinary approach provide evidence-based insights for welding challenges?

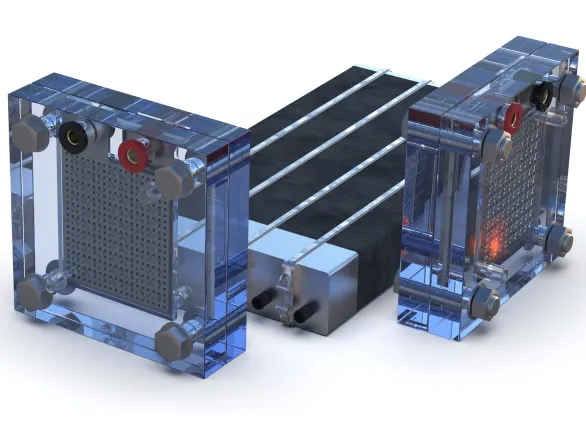

Joints and components that have been fabricated via welding, brazing, and soldering are crucial for the strength, function, and safety of numerous products and structures across a variety of industries. Exponent's licensed professional engineers and certified welding inspectors help you evaluate your welding and joining needs — whether working in heavy equipment manufacturing, biomedical devices, automotive, aerospace, oil and gas, food processing, construction, shipping and offshore structures, electronics, batteries, or heat exchangers.

Our materials engineers have significant experience conducting weld failure investigations, identifying relevant potential failure modes and defects in joints, and providing mitigation strategies for joining issues. Oftentimes, we employ a multidisciplinary approach to the analysis of welds and welding, such as collaborative investigations with our structural engineers to evaluate welds used in construction, or our mechanical engineers to evaluate welded connections via finite element analysis.

In addition to welding and joining engineering, our multidisciplinary teams provide analysis associated with welding processes, including occupational safety. Exponent's health scientists evaluate the health effects of welding fumes on workers, and our thermal scientists have consulted on issues related to actual welding-related fires and explosions. Welding safety also includes addressing physical, electrical, radiation, pressure, and other hazards in the welding environment.

Services

For 50+ years, we've thrived on solving unstructured problems that require bespoke solutions. Some of our services include:

• Process and joint design; joining method, material, and parameters selection

- Arc welding (GTAW, GMAW, SMAW, etc.)

- Laser welding

- Electron beam welding

- And more

• Metallurgical characterization and assessment

• Defect and weld failure analysis

• Welding code compliance

• Quality control, process audit, and process safety

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Batteries & Energy Storage

Supercharge performance, reliability, and safety across all stages of the battery and energy storage product lifecycle.

![[MCE] Factory Auditing & Assembly Line Evaluations - view of assembly line floor](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1320950393.jpg.webp?itok=JflDDR6c)

Materials & Corrosion Industry Expertise

Materials science engineering expertise tailored for every industry.

Product & Process Advisory

Materials and corrosion engineers assist with materials issues at every stage of your product or process lifecycle.

Materials, Metallurgy & Corrosion Engineering Capabilities

Assess corrosion risks and follow best practices in materials selection, operations, and corrosion control for metals.

Materials & Corrosion Engineering Expertise for Disputes

Technical scientific support for disputes involving materials and corrosion.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President and Principal Engineer

Practice Director and Principal Engineer

Office Director and Principal Engineer

Insights