![Fire Protection Engineering [TS]](/sites/default/files/styles/fifty_media_large/public/media/images/GettyImages-1180177143.jpg.webp?itok=qgv9WofK)

From In-house Testing to Onsite Inspections

Using specialized equipment, our experts can determine the material fire properties of products ranging from furniture and mattress components to wall covering materials and electrical wire/cable coverings. Our team of licensed professional engineers (PEs) and certified fire and explosion investigators (CFEIs) performs onsite inspections and consults with manufacturers on optimizing fire suppression systems and combustion systems.

A Dedicated Fire Team and Facility

From explosions to fire protection systems, our Bowie lab specializes in customized fire-testing and protocol development for a broad range of needs.

Bowie Laboratory: Methods, Capabilities, and Equipment

To supplement analytical, experimental, and field-based activities, our team uses computational fluid dynamic (CFD) modeling to create an accurate simulation of the burning material, support fire origin and cause determinations in the forensic environment, and provide performance-based evaluations of industrial applications.

Other analysis includes flash point testing, UL 94 burn testing for plastic components, and flammability testing cabinets for clothing and textiles.

The FETS Lab also performs in-house overhead research in areas such as smoke alarms to further the development of fire protection engineering.

Capabilities

Heat release rate and mass loss rate

Intermediate-scale calorimetry

Smoke and heat detector testing

Flash point and fire point testing

Fabric and textile flammability testing

Upholstered furniture and mattress component and mock-up testing

Pressure and leak testing

Thermal hazard testing

Hot surface ignition testing

Customized testing scenarios

Accident reconstruction

Equipment and Instrumentation

Cone calorimeter

Oxygen consumption calorimetry

Product/material comparison

Measurements

Heat release rate (HRR)

Mass loss rate (MLR)

Effective heat of combustion (∆Hc)

Critical heat flux

Ignition time

Smoke production rate

CO/CO2 production rates/yields

Flammability test cabinets

45° flammability test

Vertical flammability test

Horizontal flammability test

Full-scale textile flammability tests

Flame Spread

UL 94: test for flammability of plastic materials for parts in devices and appliances

Exhaust hood system

Intermediate-scale fire tests

Capable of handling fires up to 500 kW in size

Pressure and flow testing rigs

Furnace

Convection and vacuum ovens

Environmental chamber

Mass and volumetric flow rates

Velocity measuring

Thermocouples and heat-flux transducers

Data acquisition systems

Infrared (IR) thermometry

Smoke and particulate analysis

Exponent Labs and Facilities

Phoenix Test and Engineering Center

Offers state-of-the-art facilities to accommodate a wide range of testing and prototyping.

Menlo Park Laboratory

Develops custom tests and test protocols, in-house at our global headquarters.

Natick Laboratory

Studies everything from how batteries corrode in phones to how medical devices corrode in humans.

Philadelphia Laboratory

Test and evaluate biomedical engineering solutions in-house and through our network of third-party labs.

Seattle Materials Testing Laboratory

Provides top failure investigation and litigation support expertise.

Bowie Fire Engineering Laboratory

Helps your products, facilities, and systems pass tough fire and explosion standards.

London Laboratory

Assists with failure analysis, quality assessment, and product development in the UK and EU.

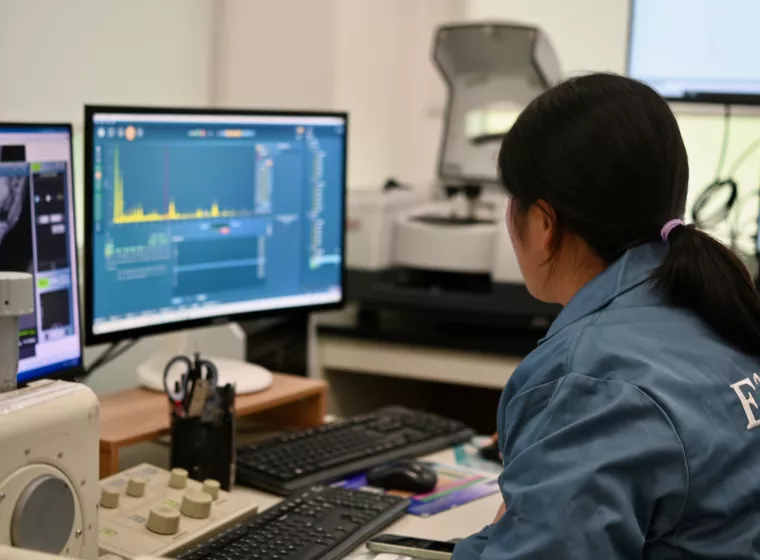

Hong Kong Laboratory

Brings extensive experience helping global manufacturers optimize products and processes.

Shanghai Laboratory

Works with global clients to support your teams in all phases of the new product integration cycle.