How can Exponent assist in solving your machine design, failure analysis, and manufacturing equipment problems?

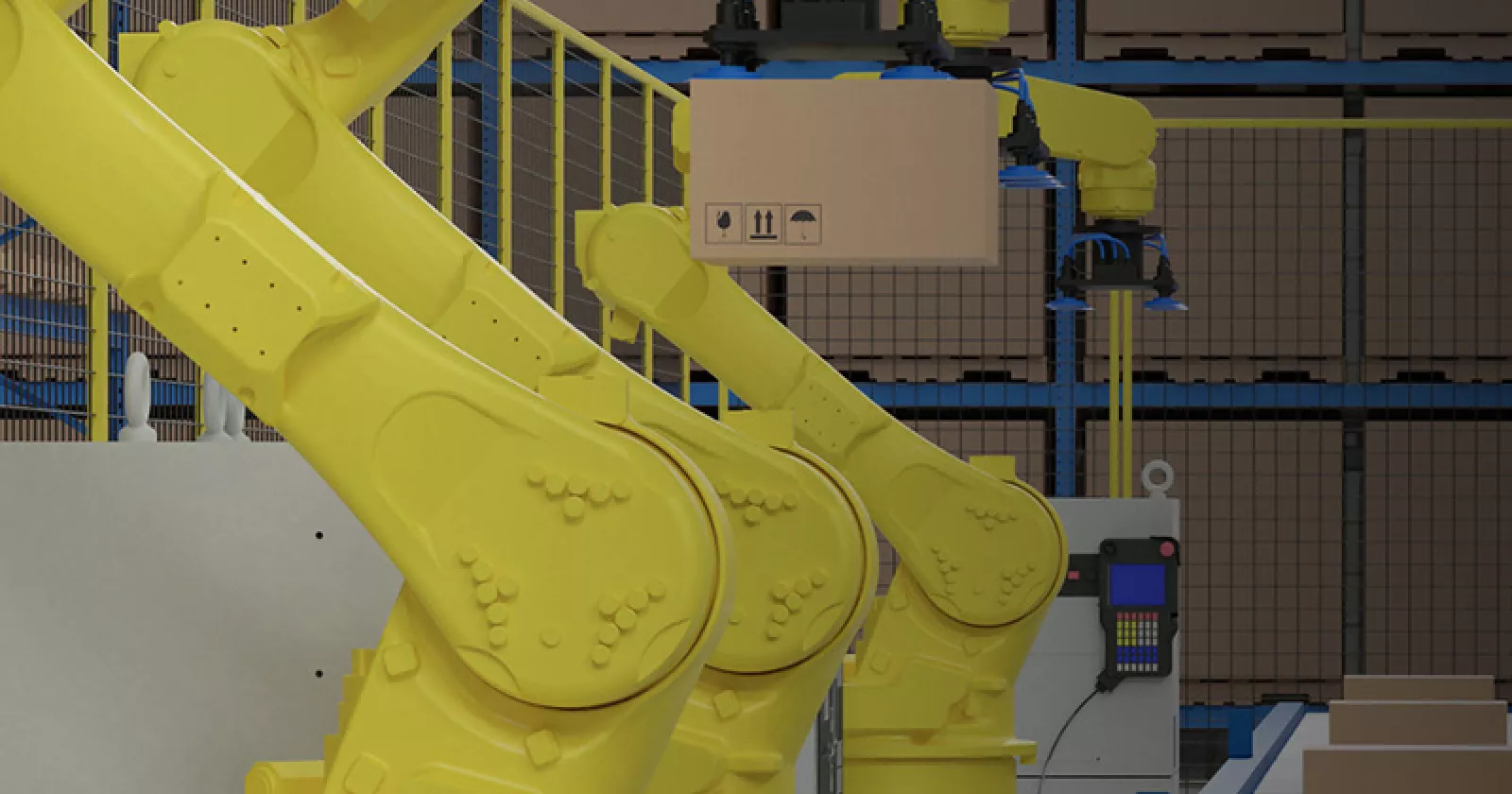

Safe, efficient industrial production and processing requires complex machinery, production tools, and integrated systems. Exponent is uniquely positioned to combine mechanical engineering and its multiple other disciplines to analyze and prevent machine and process failures and improve production efficiency and quality across industries including mineral processing, primary metals production, fabrication, and product assembly.

Our mechanical engineers, computer scientists, data scientists, electrical engineers, and other subject matter experts draw on advanced training and real-life experience to evaluate complex mechanical failures and develop innovative solutions for industrial production and processes.

For more than five decades, Exponent has been the industry leader in failure analysis and testing services of mechanical systems and components. Our work spans every industry and includes more than 90 scientific and engineering disciplines.

Services

We draw on 50+ years of experience to conduct rigorous analysis of your industrial machines and manufacturing processes and empower you to move forward with clarity and confidence.

• Design Reviews

• Laboratory testing services

• Full product-lifecycle testing and evaluation services

• Safety compliance evaluations

• Failure analysis

• Predictive modeling

• Lifetime predictions and fitness-for-service testing

• Hazard and risk assessments

• Regulatory and safety compliance reviews

• Mechanical design support

• Project management consulting

• Onsite evaluations of facilities and equipment

• Warranty and recall consulting

Capabilities

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President and Principal Engineer

Corporate Vice President and Principal Engineer

Related Expertise

Insights