How can Exponent help you accurately assess and evaluate toxicity in products and the environment?

Humans are exposed to thousands of chemical toxins through the air, water, industrial waste, and soil, as well as consumer products, medical implants and devices, and everyday household products. Exponent provides critical insights for resolving questions related to toxicity and evaluating risks for a wide variety of substances and products — from household disinfectants, cosmetics, and consumer products, to industrial solvents, industrial waste, and other pollutants.

Our toxicologists are recognized for their decades of experience advancing the fields of toxicology and exposure assessment, mechanistic biology, and human health risk assessments. For 50 years, we've helped clients with chemical exposures, regulations, and labeling requirements for consumer products as well as industrial settings.

How does our multidisciplinary approach provide unique support for challenges related to environmental toxicology?

Our multidisciplinary teams include professionals with expertise in environmental toxicology, occupational medicine, clinical toxicology, public health, regulatory safety, and industrial hygiene, and are experienced in assessing the risks posed by chemicals and other agents to help clients identify ways to mitigate their impact.

Our extensive experience in toxicology and global regulatory knowledge in chemicals, pesticides, pharmaceuticals, cosmetics, medical devices, and emerging technologies allows us to evaluate the mechanisms by which a substance may affect biological systems, offer insight on potential effects at realistic or intended human and environmental exposure levels, and provide technical support for strategies to mitigate risks.

Exponent works with the most innovative brands assisting in the development, testing, and analysis of industrial chemicals, medical devices, wearable electronics, and consumer products.

Our experts publish extensively and serve on various expert panels convened by professional societies, industry coalitions, and regulatory agencies.

Capabilities

Our Capabilities Are Unparalleled

With expertise in over 90 disciplines and hundreds of capabilities, tools, and methodologies — we get to the root of even the most complex challenges and give you the objective answers you need.

Multidisciplinary Expertise to Support the Life Sciences Industry

Support for next-gen medical devices, wearable technologies, and pharmaceutical products.

Emerging Infectious Diseases

Scientific research, strategy, and tactics to support strategic planning related to numerous aspects of emerging infectious diseases.

Healthcare and Life Sciences Value & Outcomes Assessment

Strategic guidance for medical product value and access, including drugs, vaccines, and medical devices.

Multidisciplinary Expertise for Pharmaceutical Testing & Modeling

Evaluate pharmaceuticals with pharmacodynamic modeling, clinical epidemiology, and pharmacoepidemiology studies.

Occupational & Environmental Epidemiology

Advanced epidemiological research and evidence-based insights from leading epidemiologists and biostatisticians.

Occupational Health

Occupational and environmental health risk assessment and mitigation strategies to help protect employee health and wellness.

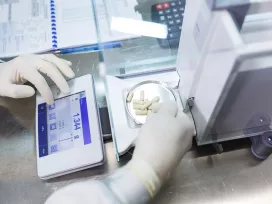

Chemical Toxicology & Health Risk Assessments

Exposure assessments, toxicity evaluations, and support for issues of toxicology and mechanistic biology.

Experts

Our global and comprehensive expertise across industries gives us a deep understanding of current challenges, best industry practices, and the implications of emerging technologies.

Group Vice President and Principal Scientist