September 16, 2025

Executive Summary

Microplastics in the environment are driving growing public attention and regulatory scrutiny; however, inconsistent definitions and a lack of standardized test methods complicate detection, analysis, and ultimately risk assessment. As regulation intensifies and public awareness grows, manufacturers, researchers, and litigators must navigate evolving standards and invest in robust, scientifically sound testing to support compliance and protect human and animal health and the environment.

Exponent offers clients deep multidisciplinary scientific expertise in selecting appropriate microplastics testing methods, interpreting results accurately, and communicating with stakeholders. Our work supports regulatory compliance and product stewardship, reduces costly missteps, and enables defensible decision-making across industries.

How do you select the right microplastics testing method and interpret its results?

Today, the world produces more than 450 million tons of plastic per year, contributing significantly to the presence of microscopic plastic fragments known as "microplastics" in the environment. According to one study, as much as 12.7 million metric tons of plastics entered the ocean in 2010 alone. Microplastics can either be intentionally added to products, such as loose plastic glitter found in certain cosmetics, or they can form through the breakdown of larger plastic items, like bottles and packaging.

While many studies have documented the presence of microplastics in the environment and estimated human exposure and subsequent effects, a lack of standardized materials, methods, and practical guidance around testing has led to uncertainty in the magnitude and consistency of effects observed in animal models and humans. In 2022, the World Health Organization released a report titled "Dietary and inhalation exposure to nano- and microplastic particles and potential implications for human health," which concluded that current data are insufficient to determine whether exposure is associated with any direct or indirect pathological effects. This is aligned with the position of the U.S. Food and Drug Administration, which states "Current scientific evidence does not demonstrate that levels of microplastics or nanoplastics detected in foods pose a risk to human health." Notably, the WHO emphasizes the need for more comprehensive studies to better understand the effects of microplastic particles on human health.

In the meantime, public concern over microplastics is on the rise. In 2022, California became the first government to mandate testing for microplastics in drinking water. Similarly, states including Connecticut, Illinois, Wisconsin, and Colorado have enacted regulations concerning the production and sale of products containing microbeads and microfibers. In response, many companies are evaluating their products to identify and quantify any microplastics content. Manufacturers and retailers of cosmetics and personal care products, in particular, are increasingly motivated to test their products for microplastics to comply with regulations or to promote them as plastic-free.

As public awareness of plastic and microplastic pollution grows, the need to test products for their presence becomes increasingly important. However, the diversity in sizes and types of microplastics presents a challenge, as regulatory agencies have yet to agree on definitions or testing methods. Until microplastic regulations are finalized, including consensus on standardized tests, manufacturers must carefully evaluate each testing method and scrutinize the results.

What are microplastics?

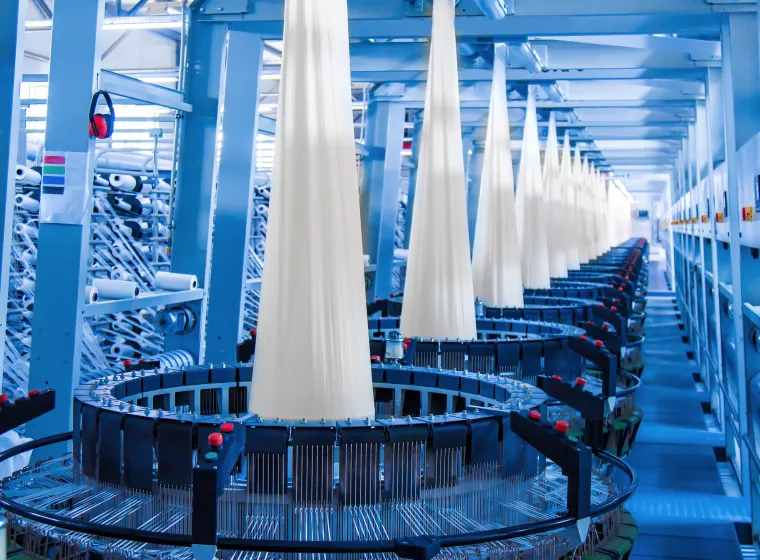

Microplastics are tiny plastic particles formed through various processes. Some cosmetics and cleaning products contain plastic microbeads to enhance exfoliation or scrubbing properties. However, many microplastics originate through fragmentation, when larger plastics, such as synthetic textiles and building materials, break down into smaller pieces due to ultraviolet radiation, wind, and wave action. Depending on their size, these microplastics can bypass water filtration systems and enter soil, oceans, and other water bodies. In the environment, microplastics can occur in soil, plants, animals, and drinking water.

Microplastics are often defined as solid plastic particles up to 5 millimeters in size. The lower size limit of microplastic definitions varies widely, and there is little consensus. This wide range presents technical challenges for characterization, particularly at the smaller end of the spectrum. Detecting particles below 1 micron (i.e., nanoplastics) is difficult and raises questions about whether or not these materials exist as solid particles at these sizes. The shape of microplastics can also vary, with some definitions distinguishing between microplastics and microfibers based on their dimensionality: microfibers are typically elongated and thread-like, while other microplastic particles can be fragments, beads, or films.

Determining whether a particle is technically a plastic requires analyzing its chemical composition, which can be particularly challenging for smaller particles and samples. Additionally, definitions of "plastic" for scientific or regulatory purposes can vary, with some definitions excluding certain biodegradable or water-soluble polymers from the category of "microplastics."

Regulatory definitions of "microplastics" vary

The Environmental Protection Agency defines microplastics as plastic particles less than 5 millimeters in size and focuses on conducting research to understand their prevalence and effects on health and the environment. The National Oceanic and Atmospheric Administration (NOAA) defines microplastics similarly but also includes a definition of microfibers, emphasizing the importance of addressing microfiber pollution, which is a significant component of marine debris.

The California State Water Resources Control Board, one of the first agencies to establish microplastic drinking water standards, has a definition that aligns with EPA's size criteria but also includes specific regulations and resolutions to address microplastic pollution in state waters. Similarly, the European Union has its own regulations, including the EU Commission Regulation 2023/2025, which amends previous regulations to include specific criteria for synthetic polymer microparticles. The EU's definition focuses on the size, shape, and chemical composition of these particles.

While seemingly minor, the differences in these definitions could impact unintended products and lead to conflicting regulatory demands in different markets. Numerous methods exist for testing samples for microplastics and performing chemical analysis on any particles found. However, deciding which tests to perform and interpreting their results can be complex. Manufacturers and organizations seeking to determine whether a product or sample contains microplastics should be aware of the challenges involved in testing for these tiny particles.

Detecting microplastics presents significant challenges due to the need for rigorous controls, the risk of background interference, and the manual and labor-intensive nature of current techniques.

How do I choose the right microplastics characterization tests?

Choosing the right experimental design, including the specific methods for sample selection, preparation and testing — and accurately interpreting results — can require expertise across fields such as polymer science, molecular biology, and ecology. The product type and conditions of expected use also factor into the decision-making related to the seemingly simple question of how to test. Without the appropriate context, manufacturers and organizations may risk misinterpreting certain test results, potentially leading to costly and misguided development efforts. Similarly, litigators without the appropriate scientific understanding of the numerous characterization techniques may struggle to explain and defend test results in court. As microplastics regulation and public opinion continue to evolve rapidly, it is crucial for stakeholders to have access to expertise in comprehensive, up-to-date, and accurate testing and analytics.

When testing for microplastics, there are multiple properties of interest, requiring analytical sensitivity and resolution over many orders of magnitude. This combination of variables is such that one instrument or method cannot accurately determine the chemical composition as well as size, distribution, and shape of particles. Typically, this results in the need to utilize multiple techniques to address key questions, such as:

Key questions

Do particles exist in a given sample? In what sizes and quantities?

Potential techniques

- Dynamic light scattering (DLS)

- Static laser light scattering (SLS)

- Microscopy

- Liquid particle counting

- Nanoparticle tracking analysis (NTA)

- Scanning Electron Microscopy or Transmission Electron Microscopy (SEM/TEM)

Key questions

If present, what is the material composition of the detected particles? Are they plastic?

Potential techniques

- Micro-Fourier Transform Infrared Spectroscopy

- Micro-Raman Spectroscopy

- Matrix-Assisted Laser Desorption/Ionization-Time of Flight Mass Spectrometry (MALDI-ToF/MS - MALDI-ToF/MS

- Pyrolysis-Gas Chromatography-Mass Spectrometry (Py-GC/MS)

What are some of the challenges of microplastics testing?

Detecting microplastics presents significant challenges due to the need for rigorous controls, the risk of background interference, and the manual and labor-intensive nature of current techniques. Although automation is being developed, microplastics testing generally remains costly and time-consuming. Careful sample preparation and quantification is crucial to prevent contamination during handling. For example, since microplastics are commonly present in the air, any particles deposited on samples during preparation or quantification can lead to overestimations. Additionally, characterization often requires processing large sample quantities to concentrate the particles. While automation can expedite the testing process, sample preparation will likely continue to require human oversight.

Another challenge in microplastics analysis is the limited number of existing methods for quantification. While California has published standard operating procedures (SOPs) for quantifying microplastics in drinking water, SOPs for other matrices, such as biological samples, sediment, water, and products, are often lacking. This absence of standardized methods can lead to variability in results and hinder the comparability of studies.

ASTM International provides standardized methods for identifying and characterizing microplastics, with standards like ASTM D8402-23 and ASTM D8489-23 offering detailed guidelines for testing and analysis. However, these standards are specific to water and are not universally or consistently applied. New guidelines for different sample matrices should be developed to improve test results. For example, high concentrations of lipids in soil and biotic samples can interfere with the analysis of polyethylene, a common type of plastic.

What does the future of microplastics testing hold?

People have been using plastic for well over 50 years, yet health and environmental microplastics research is still a burgeoning field. Biologists and epidemiologists are uncertain about the extent of the health risks these particles may pose and their impact on ecosystems and the environment. Some studies have indicated tentative links between microplastics and health outcomes, but even when associations are identified, the mechanisms by which microplastics interact with biological systems on a cellular and molecular level remain largely unknown.

Research may eventually uncover specific mechanisms behind potential ecological or health impacts of microplastics. In the meantime, many governments are striving to reduce the presence of microplastics in the environment and among their populations. This effort will likely lead to increased regulation, more rigorous testing, and enhanced environmental cleanup and remediation efforts. Stakeholders will benefit from developing a better understanding of which testing methods to use and how to employ them effectively to achieve accurate, verifiable results, support regulatory compliance, and improve product safety and sustainability.

Frequently Asked Questions

What Can We Help You Solve?

Exponent closely monitors the continually changing plastics regulatory landscape to help clients prepare for new regulations. Our experts have years of experience with the U.S. and international regulatory environments, including consumer product assessments, design support, and product stewardship evaluations.

Designing Plastic Products for Sustainability & Recyclability

Design plastics recyclability and sustainability into your whole product lifecycle.

Sustainability

Meet changing sustainability regulations with rigorous science and experienced consulting services.

Plastics in the Environment

Develop proactive plans to mitigate the environmental impact of polymer and plastic waste.

Polymers Expertise for Consumer Products

Rigorous testing and analysis of polymers in consumer products.

Polymers Used for Food & Beverage Packaging

Create safer, compliant, and high-performing food and beverage products.

![Quality analysis [PSMC]](/sites/default/files/styles/cards_home_card/public/media/images/GettyImages-1221176906.jpg.webp?itok=iXimIDYr)

Quality Analysis of Polymers

Understand complex polymers and material manufacturing challenges throughout the product and process lifecycle.